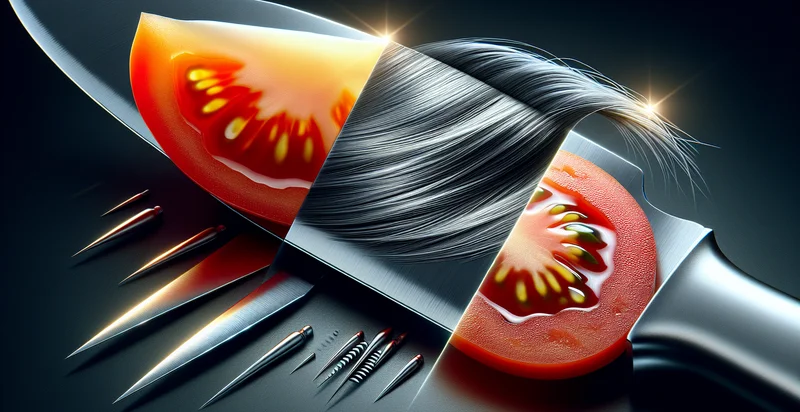

Identify worn vs new blade

using AI

Below is a free classifier to identify worn vs new blade. Just upload your image, and our AI will predict if the blade is worn or new - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("worn-vs-new-blade", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/worn-vs-new-blade/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/worn-vs-new-blade/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the blade is worn or new.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including New Blade and Worn Blade.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the blade is worn or new).

Whether you're just curious or building worn vs new blade detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify worn vs new blade at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Industrial Maintenance: In manufacturing settings, the worn vs. new blade identifier can proactively monitor cutting tools and blades on production lines. This helps maintenance teams schedule timely replacements, reducing downtime and improving overall efficiency.

- Quality Control in Manufacturing: By integrating the blade identifier into quality assurance systems, manufacturers can automate the inspection process for cutting tools. This ensures only properly maintained tools are used, leading to higher product quality and less waste.

- Tool Rental Services: Rental companies can utilize the worn vs. new blade identifier to assess the condition of blades before renting them out to customers. This enables accurate grading of tools and helps in maintaining customer satisfaction by providing reliable equipment.

- Cost Management for Construction Projects: Construction firms can implement this identifier to monitor the condition of blades used in various tools, enabling better budgeting for tools maintenance and replacement. This leads to optimized spending and resource allocation on projects.

- E-commerce and Retail Insights: Online retailers can use the classification function to analyze product returns related to worn tools. By identifying trends and patterns of wear, companies can adjust their inventory and marketing strategies to better serve customer needs.

- Training and Safety Compliance: Organizations can employ the worn vs. new blade identifier in training programs for new employees. This technology aids in demonstrating safe tool usage and the importance of identifying worn equipment to prevent workplace accidents.

- Predictive Analytics in Tool Manufacturing: Tool manufacturers can leverage this classification function to gather metrics on blade wear over time. Insights gained from data analysis can drive innovations in blade design and material selection to enhance product longevity and performance.