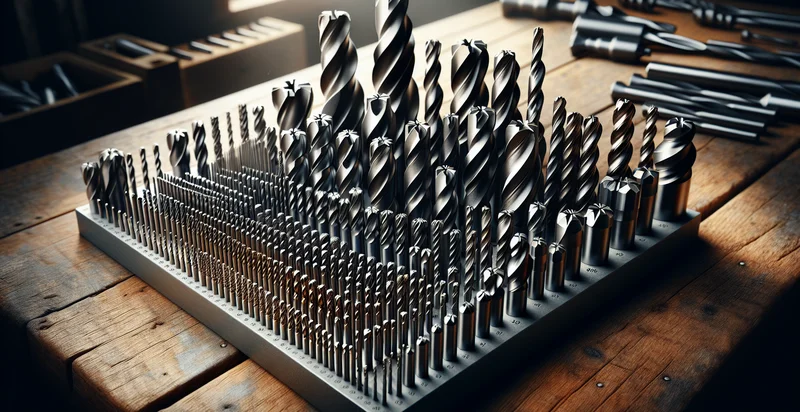

Identify width of drill bit in inches

using AI

Below is a free classifier to identify width of drill bit in inches. Just upload your image, and our AI will predict the width of the drill bit in inches. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("width-of-drill-bit-in-inches", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/width-of-drill-bit-in-inches/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/width-of-drill-bit-in-inches/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the width of the drill bit in inches..

This pretrained image model uses a Nyckel-created dataset and has 15 labels, including 1 Foot, 1 Inch, 10 Inches, 11 Inches, 12 Inches, 2 Inches, 3 Inches, 4 Inches, 5 Inches and 6 Inches.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the width of the drill bit in inches.).

Whether you're just curious or building width of drill bit in inches detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify width of drill bit in inches at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: This use case involves using the false image classification function to identify defects in drill bits based on their width specifications. By ensuring that only drill bits meeting required dimensions are sent to market, manufacturers can reduce waste and improve product reliability.

- Inventory Management: Retailers can employ this function to verify the dimensions of drill bits during the inventory intake process. Accurately classifying the width of drill bits helps maintain accurate inventory records, ensuring the right products are available for customer purchases.

- E-commerce Product Verification: Online retailers can utilize this function to confirm that the drill bits received from suppliers match the specified widths in product listings. This ensures customer satisfaction by eliminating discrepancies in product dimensions that may lead to returns or negative reviews.

- Automated Packaging Systems: In automated warehouses, this function can be integrated into packaging systems to classify drill bits prior to shipping. By verifying the width of drill bits, the system can ensure that the correct items are packaged and shipped to customers.

- Compliance with Industry Regulations: Manufacturers can use this function to ensure that their drill bits comply with regulatory standards related to tool dimensions. By verifying the width through image classification, companies can avoid legal issues and potential recalls stemming from non-compliance.

- Tool Calibration and Testing: Tool rental companies can employ this function to regularly classify the width of drill bits returned from customers. This classification helps in assessing the wear and tear of tools, ensuring they are properly calibrated before being rented out again.

- Supply Chain Optimization: Distributors can use the image classification function during the receiving phase of the supply chain to minimize errors in shipment. By verifying the width of drill bits, they can streamline operations and enhance accuracy in fulfilling orders to clients.