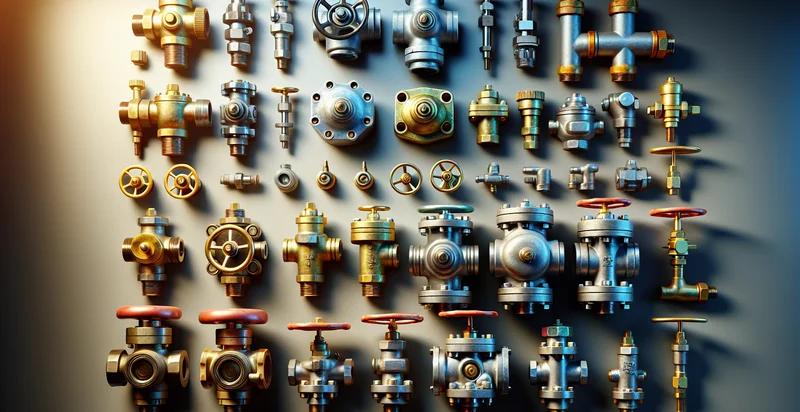

Identify valve configurations

using AI

Below is a free classifier to identify valve configurations. Just upload your image, and our AI will predict the type of valve configuration it is - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("valve-configurations", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/valve-configurations/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/valve-configurations/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the type of valve configuration it is.

This pretrained image model uses a Nyckel-created dataset and has 25 labels, including Ball Valve, Butterfly Valve, Check Valve, Cross Flow, Diaphragm Valve, Dohc, Flat, Floating Valve, Gate Valve and Globe Valve.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the type of valve configuration it is).

Whether you're just curious or building valve configurations detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify valve configurations at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Improved Safety Monitoring: The valve configurations identifier can enhance industrial safety by automatically detecting incorrect or dangerous valve configurations in real-time. By continuously monitoring these configurations, operators can receive alerts, preventing potential leaks or accidents.

- Predictive Maintenance: This function can be integrated into maintenance systems to predict when valve configurations are likely to fail. By analyzing historical data and current configurations, the system can schedule maintenance proactively, thus reducing unexpected downtime.

- Quality Control in Manufacturing: In manufacturing environments, the valve configurations identifier can ensure that all valves are set correctly before products leave the production line. This helps maintain product quality and reduces the risk of recalls or rework caused by improperly set valves.

- Regulatory Compliance: Industries such as oil and gas, pharmaceuticals, and chemicals must adhere to strict regulations. The valve configurations identifier can document compliance by verifying that all valves are in the correct configurations, thus aiding in audits and inspections.

- Remote Monitoring and Management: The function can enable remote monitoring of valve configurations, allowing operators to manage systems from various locations. This is especially beneficial for facilities in remote areas, reducing the need for on-site personnel and improving operational efficiency.

- Training and Simulation: The valve configurations identifier can serve as a training tool for new employees by simulating various valve configurations and their implications. Trainees can learn to identify correct and incorrect settings, improving their skills without risking actual system performance.

- Integration with IoT Systems: By incorporating the valve configurations identifier into IoT platforms, businesses can create a more connected and intelligent operational framework. This integration can facilitate data sharing between devices, allowing for smarter decision-making and enhanced workflow optimization.