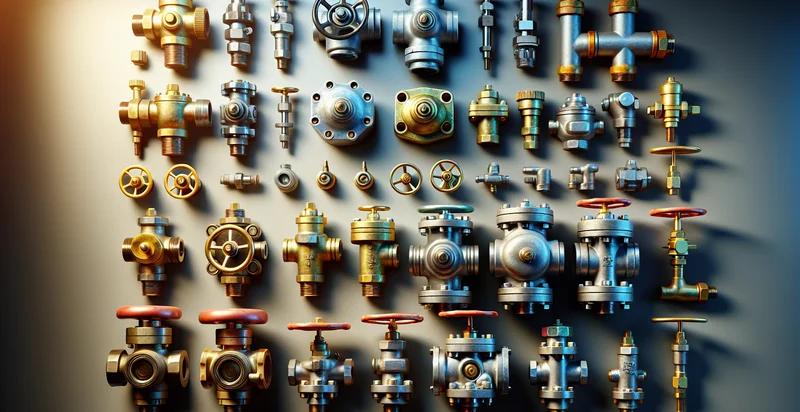

Identify valve conditions

using AI

Below is a free classifier to identify valve conditions. Just upload your image, and our AI will predict the operational state of the valves. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("valve-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/valve-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/valve-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the operational state of the valves..

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Adjusted, Blocked, Corroded, Damaged, Leaky, Loose, Normal, Stuck, Tight and Worn.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the operational state of the valves.).

Whether you're just curious or building valve conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify valve conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: The false image classification function can be employed to identify potential valve condition failures before they occur. By analyzing images from valves in real-time, the system can flag anomalies, allowing maintenance teams to address issues proactively and reduce downtime.

- Quality Control in Manufacturing: In manufacturing setups where valves are produced, integrating this classification function can enhance quality control processes. The system can automatically detect and classify defective valves by assessing their images against standard condition criteria, ensuring only quality products reach customers.

- Asset Management: Businesses can leverage the valve conditions identifier to maintain a detailed inventory of valves employed in different applications. By continuously monitoring and classifying images of valves in the field, organizations can optimize asset lifecycles and allocate resources more effectively.

- Compliance Monitoring: Regulatory compliance in industries like oil and gas or water management often requires regular inspections of valves. This classification function can automate visual inspections, helping organizations prove compliance with safety and environmental standards through documented evidence of valve conditions.

- Remote Inspection: In remote or hazardous environments, deploying the false image classification function can streamline valve inspections. Drones or robotic systems equipped with cameras can capture valve images, and the classification system can analyze these remotely, minimizing the risk to human inspectors.

- Incident Reporting and Analysis: Businesses can use this function to assess valve images associated with incidents and failures. By classifying these images, organizations can identify patterns or recurring issues, facilitating root cause analysis and enhancing operational safety.

- Enhanced Customer Support: Service teams can utilize the valve conditions identifier tool to assist customers experiencing valve-related issues. By allowing customers to submit images of their valves, the system can classify and diagnose problems, leading to quicker resolutions and improved customer satisfaction.