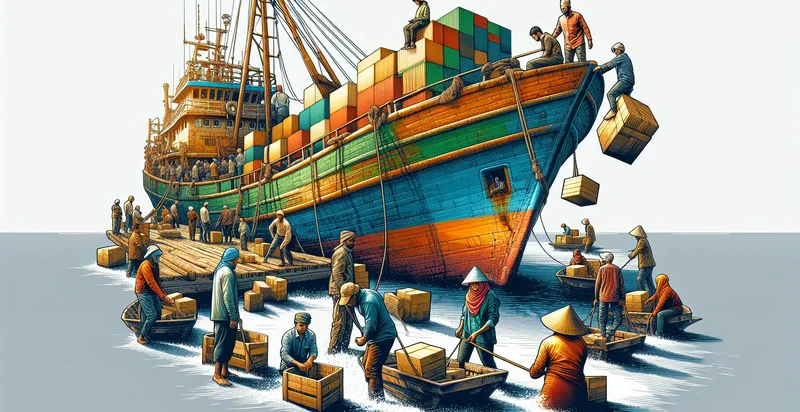

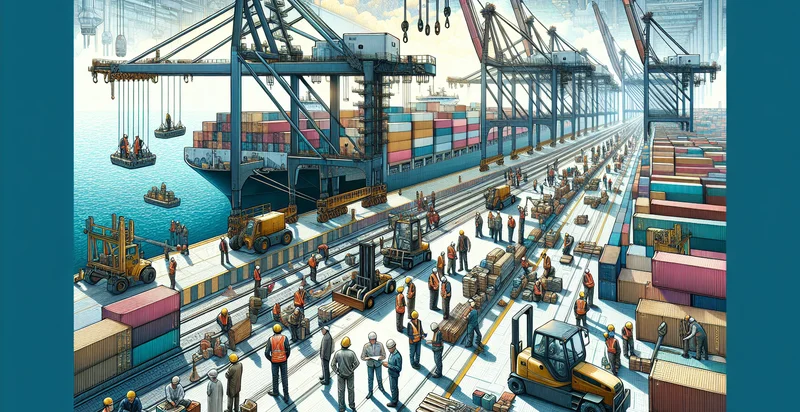

Identify unloading conditions

using AI

Below is a free classifier to identify unloading conditions. Just upload your image, and our AI will predict the unloading conditions of various materials - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("unloading-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/unloading-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/unloading-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the unloading conditions of various materials.

This pretrained image model uses a Nyckel-created dataset and has 20 labels, including Communication Effectiveness, Environmental Hazards, Equipment Status, Facility Readiness, Incident History, Loading Dock Accessibility, Manpower Allocation, Material Availability, Regulatory Requirements and Safety Compliance.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the unloading conditions of various materials).

Whether you're just curious or building unloading conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify unloading conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: This function can be integrated into manufacturing lines to identify false images or products that do not meet quality standards during unloading procedures. By automating this process, manufacturers can reduce defects and improve overall production efficiency, ensuring that only high-quality products proceed to the next stage.

- Supply Chain Optimization: By employing the unloading conditions identifier, logistics companies can better manage and streamline their unloading processes. The function helps in quickly classifying and verifying incoming goods, enabling faster inventory checks and reducing delays in the supply chain.

- Agricultural Produce Inspection: In agriculture, this function can classify images of crops and products during unloading to detect any produce that is damaged or substandard. This capability ensures that only the best quality goods are sent to market, maximizing the value of agricultural outputs.

- Retail Inventory Management: Retailers can utilize the unloading conditions identifier to evaluate stock deliveries upon arrival. By quickly identifying any discrepancies or issues through false image classification, they can ensure proper inventory levels and improve overall stock management.

- Hazardous Material Recognition: In industries dealing with hazardous materials, this function can identify and classify unloading conditions to ensure that potentially unsafe materials are recognized and handled appropriately. This can enhance workplace safety protocols and compliance with regulations.

- Autonomous Vehicle Loading and Unloading: This technology can be implemented in autonomous vehicles to ensure correct loading and unloading conditions are met. By classifying images of cargo, the system can prevent mishaps and improve operational efficiency in self-driving logistics systems.

- Construction Site Material Validation: Construction companies can use the unloading conditions identifier to validate the incoming materials at job sites. By automatically checking for discrepancies in what was ordered versus what is delivered, they can avoid delays and ensure project timelines are met effectively.