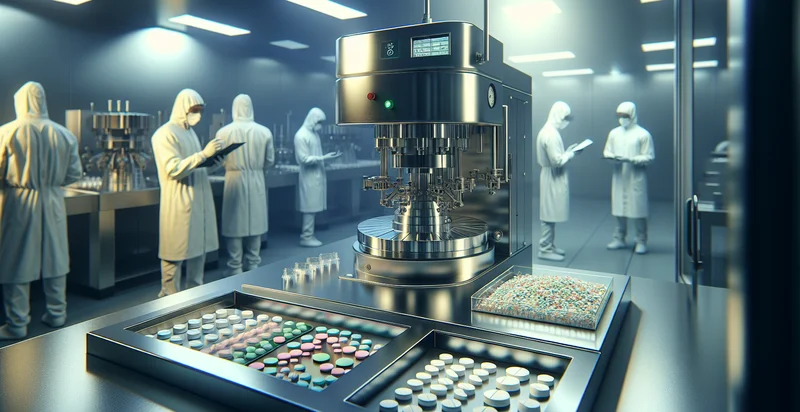

Identify tablet press conditions

using AI

Below is a free classifier to identify tablet press conditions. Just upload your image, and our AI will predict the optimal tablet press conditions for different formulations - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("tablet-press-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/tablet-press-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/tablet-press-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal tablet press conditions for different formulations.

This pretrained image model uses a Nyckel-created dataset and has 4 labels, including Excellent Condition, Fair Condition, Good Condition and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal tablet press conditions for different formulations).

Whether you're just curious or building tablet press conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify tablet press conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

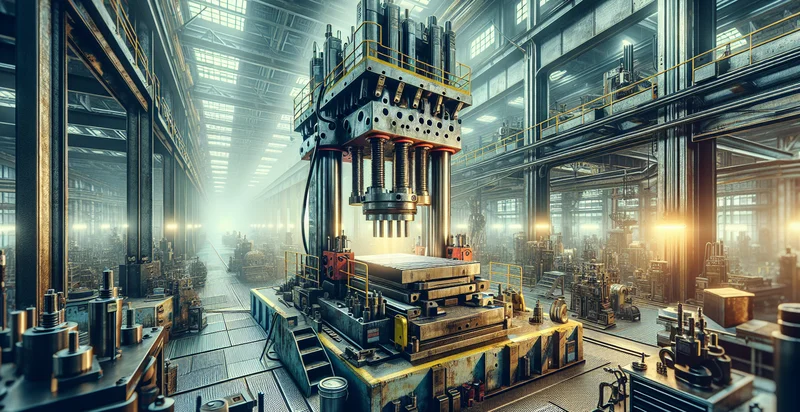

- Quality Control in Manufacturing: This use case involves implementing a false image classification function to ensure that tablet press conditions are optimized during the production process. By identifying incorrect tablet images, manufacturers can reduce defects and maintain consistent product quality.

- Predictive Maintenance: The false image classification function can be utilized to monitor equipment performance in tablet pressing machines. By analyzing images of press conditions, it can identify potential malfunctions before they lead to costly downtime, enabling proactive maintenance.

- Compliance Verification: Pharmaceutical companies can use this function to verify that tablet press conditions comply with industry regulations. By classifying images and identifying any discrepancies, companies can ensure adherence to good manufacturing practices (GMP) and avoid regulatory penalties.

- Research and Development: In R&D, this function can assist in experimenting with different tablet press conditions. By analyzing the resulting images of tablets formed under various settings, researchers can quickly identify optimal conditions for new formulations or product improvements.

- Supplier Quality Assurance: When sourcing tablets from third-party manufacturers, this classification function can be employed to assess the quality of tablets received. By comparing sample images against established standards, companies can ensure their suppliers meet the necessary quality benchmarks.

- Training for Operators: This use case involves using the image classification function as a training tool for production operators. By illustrating what correctly pressed tablets look like versus incorrectly pressed ones, operators can enhance their skills and reduce the learning curve in identifying issues.

- Continuous Improvement Programs: Companies can integrate the false image classification function into their continuous improvement initiatives. By regularly analyzing tablet conditions through classified images, they can identify trends over time, implementing strategies to enhance efficiency and reduce waste in the production process.