Identify sterilization equipment conditions

using AI

Below is a free classifier to identify sterilization equipment conditions. Just upload your image, and our AI will predict the condition of sterilization equipment. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("sterilization-equipment-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/sterilization-equipment-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/sterilization-equipment-conditions/invoke

How this classifier works

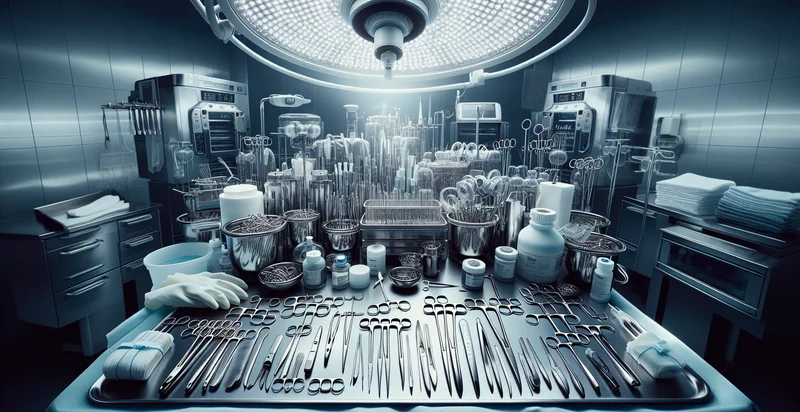

To start, upload your image. Our AI tool will then predict the condition of sterilization equipment..

This pretrained image model uses a Nyckel-created dataset and has 8 labels, including Fair Condition, Functional Condition, Good Condition, Like New Condition, Non-Functional Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of sterilization equipment.).

Whether you're just curious or building sterilization equipment conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify sterilization equipment conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

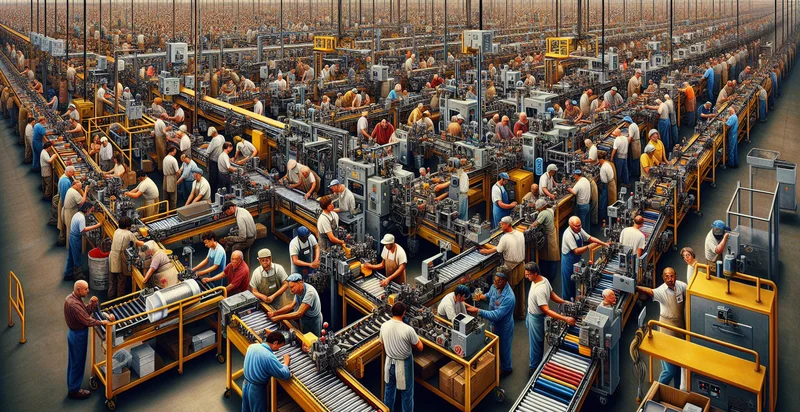

- Quality Control in Manufacturing: The false image classification function can be utilized to ensure that sterilization equipment is functioning correctly during the manufacturing of medical devices. By analyzing images of sterilization processes, the system can identify any deviations from expected conditions, helping manufacturers adhere to regulatory standards and quality assurance protocols.

- Maintenance Prediction: This function can aid in predictive maintenance of sterilization equipment by identifying visual indicators of wear and tear. By continuously monitoring operational conditions through image classification, businesses can schedule maintenance proactively, reducing downtime and extending equipment life.

- Compliance Verification: Hospitals and laboratories often face strict compliance requirements for sterilization processes. The false image classification function can verify that sterilization conditions are met by analyzing images of sterilized instruments, ensuring adherence to health and safety regulations.

- Inventory Management: In environments where sterilization equipment is used, managing inventory is crucial. This function can classify images of sterilized items, helping to track inventory levels and ensuring that sufficient quantities of necessary instruments are available while minimizing waste.

- Training and Education: The classification function can be implemented in training programs for staff operating sterilization equipment. By providing visual feedback on optimal conditions versus false classifications, it enhances learning and reinforces best practices for effective sterilization.

- Root Cause Analysis: If there are discrepancies in sterilization outcomes, the image classification function can assist in root cause analysis. By analyzing resulting images, it helps identify issues related to equipment conditions, materials used, or operator error, improving incident response and preventing future occurrences.

- Reporting and Analytics: Companies can leverage this function to generate reports that detail the performance of sterilization equipment over time. By classifying images and conditions, it provides valuable analytics that can inform process improvements and support strategic decision-making in operational efficiency.