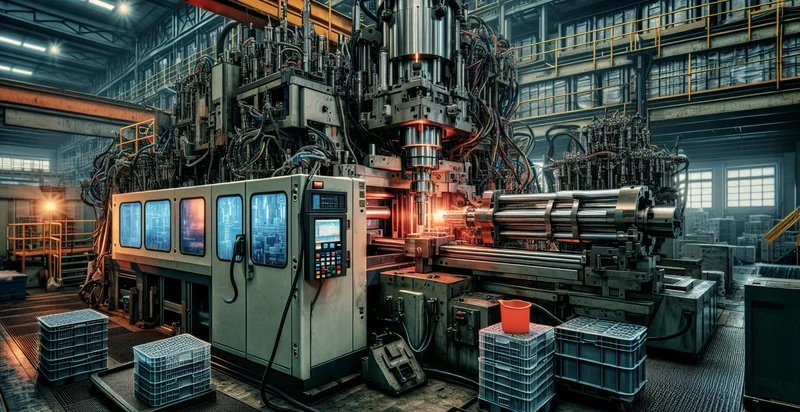

Identify sorting machine conditions

using AI

Below is a free classifier to identify sorting machine conditions. Just upload your image, and our AI will predict the optimal conditions for sorting machines - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("sorting-machine-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/sorting-machine-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/sorting-machine-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal conditions for sorting machines.

This pretrained image model uses a Nyckel-created dataset and has 8 labels, including Average Condition, Bad Condition, Excellent Condition, Fair Condition, Good Condition, Like New Condition, Poor Condition and Very Good Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal conditions for sorting machines).

Whether you're just curious or building sorting machine conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify sorting machine conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

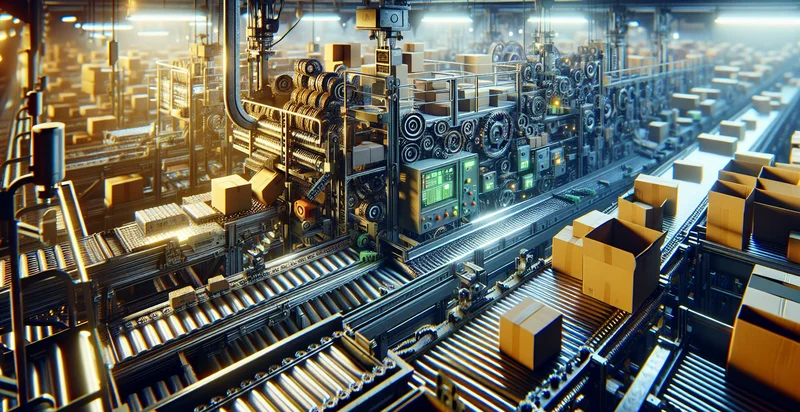

- Equipment Health Monitoring: This function can be used to classify the conditions of machines in real time, allowing operators to monitor the health of equipment. By identifying false images of machine conditions, organizations can reduce unnecessary maintenance tasks and improve operational efficiency.

- Predictive Maintenance: By utilizing the false image classification function, companies can predict potential machine failures before they occur. This proactive approach minimizes downtime and saves on costs associated with emergency repairs and production losses.

- Quality Control in Manufacturing: The classification function can aid in distinguishing between acceptable machine conditions and those leading to faulty products. This ensures that only machines in optimal condition are used in production, thereby enhancing product quality and reducing waste.

- Inventory Optimization: Using false image classification can help identify underperforming assets and machines that are frequently in poor condition. This information allows businesses to optimize inventory by retiring or replacing equipment that doesn't meet performance standards.

- Environmental Compliance: Industries that need to adhere to strict environmental regulations can use this function to classify machine conditions that may contribute to violations. By identifying and addressing these conditions, companies can maintain compliance and avoid costly fines.

- Remote Monitoring Solutions: The function can be integrated into remote monitoring systems to analyze machine health from a distance. This benefits organizations with multiple locations, allowing them to oversee machine conditions without being physically present.

- Training and Development: The false image classification capabilities can be employed to create training modules for operators and maintenance staff. By simulating various machine conditions, employees can learn how to identify and respond to issues effectively, improving overall operational readiness.