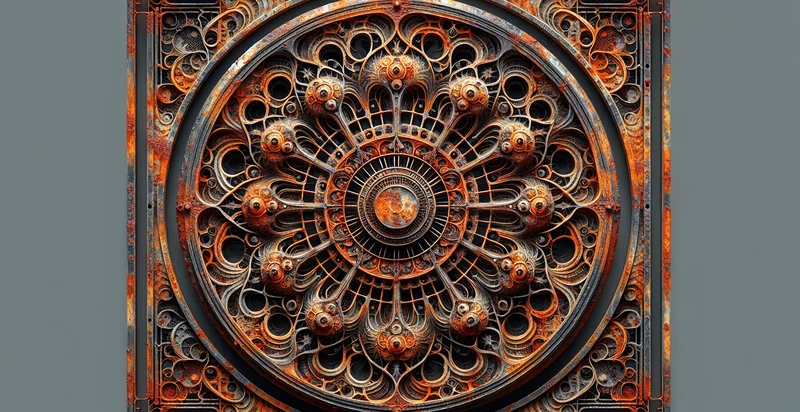

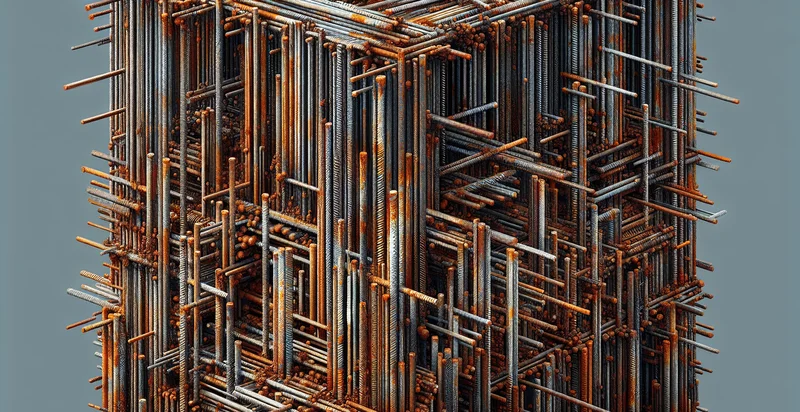

Identify rust presence

using AI

Below is a free classifier to identify rust presence. Just upload your image, and our AI will predict if there is rust present - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("rust-presence", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/rust-presence/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/rust-presence/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if there is rust present.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Clean and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if there is rust present).

Whether you're just curious or building rust presence detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify rust presence at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Industrial Equipment Maintenance: Implementing a rust presence identifier can enhance predictive maintenance for heavy machinery across various industries. By monitoring equipment for signs of rust, companies can schedule timely repairs or replacements, preventing costly downtime and extending asset lifespan.

- Quality Control in Manufacturing: A rust identification system can be integrated into manufacturing lines to ensure the quality and durability of metal components. By detecting rust early in the production process, manufacturers can reduce defects and maintain higher standards for their products.

- Infrastructure Inspection: Municipalities and engineering firms can use rust detection technology for the inspection of bridges, buildings, and other structures. Early identification of rust allows for proactive maintenance strategies, enhancing public safety and reducing the risk of structural failures.

- Automotive Industry Monitoring: Automotive manufacturers and service centers can utilize rust presence detection to monitor vehicles during production and servicing. Identifying rust ensures that cars meet safety standards and that vehicles are protected against corrosion during their lifecycle.

- Supply Chain Quality Assurance: Companies involved in the procurement of metal materials can use rust detection systems to assess the quality of incoming shipments. This helps ensure that only non-corroded materials are used in production, minimizing defects and maintaining product integrity.

- Marine Vessel Inspection: The shipping and maritime industry can implement rust identification for regular maintenance checks on vessels. Detecting rust on hulls and other components helps prevent structural failures and ensures compliance with safety regulations.

- Energy Sector Asset Management: In the oil and gas and renewable energy sectors, identifying rust in pipelines and equipment can be crucial to safety and operational efficiency. Using a rust presence identifier allows companies to anticipate maintenance needs, reduce environmental risks, and enhance the overall reliability of their operations.