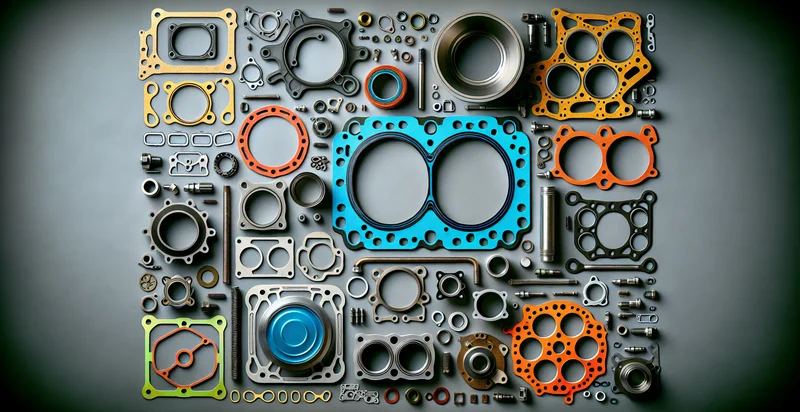

Identify rotor diameters

using AI

Below is a free classifier to identify rotor diameters. Just upload your image, and our AI will predict the class of rotor diameters it belongs to - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("rotor-diameters", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/rotor-diameters/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/rotor-diameters/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the class of rotor diameters it belongs to.

This pretrained image model uses a Nyckel-created dataset and has 20 labels, including 10Inch, 12Inch, 14Inch, 16Inch, 18Inch, 20Inch, 22Inch, 24Inch, 26Inch and 28Inch.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the class of rotor diameters it belongs to).

Whether you're just curious or building rotor diameters detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify rotor diameters at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

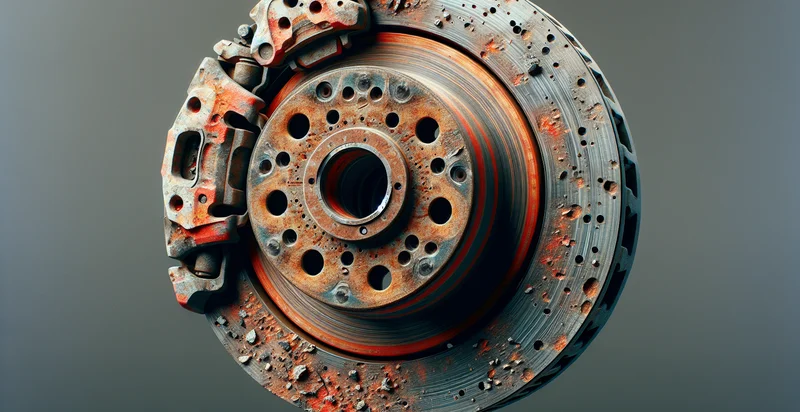

- Quality Control for Manufacturing: The rotor diameter identifier can be used in manufacturing quality control processes to ensure products meet specified dimensions. By integrating this function into inspection systems, manufacturers can automatically detect discrepancies in rotor sizes, reducing defects and waste.

- Inventory Management: Companies that produce or store rotors can use the identifier to streamline inventory management. By automatically classifying rotor diameters, businesses can enhance their tracking systems, ensuring that the right sizes are always available for demand fulfillment.

- Predictive Maintenance: In industries relying on machinery with rotors, such as aviation or automotive, the diameter identifier can assist in predictive maintenance efforts. By monitoring rotor diameters, companies can predict when parts may need servicing or replacement based on wear and operational demands.

- Design Optimization: Engineers can utilize the rotor diameter identifier during the research and development phase to test and optimize rotor designs. By analyzing classifications of different diameters, teams can better understand performance characteristics and make informed decisions to enhance efficiency.

- Data Analytics in Supply Chain: Businesses can leverage the rotor diameter identifier for advanced data analytics across their supply chain. By correlating rotor dimensions with performance data, companies can identify trends or issues in their material sourcing and production processes.

- Automated Sorting Systems: The function can be integrated into automated sorting systems in warehouses or manufacturing plants. By enabling precise classification of rotor diameters, businesses can improve sorting efficiency and minimize human error during order fulfillment.

- Regulatory Compliance Reporting: Industries subject to regulatory standards regarding component dimensions can utilize the rotor diameter identifier to ensure compliance. By automating the classification of rotor sizes, companies can streamline reporting processes and improve accuracy in meeting regulatory requirements.