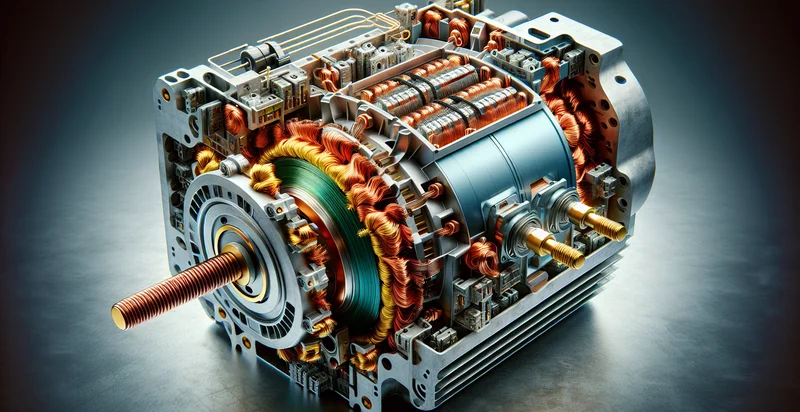

Identify pump conditions

using AI

Below is a free classifier to identify pump conditions. Just upload your image, and our AI will predict the condition of the pump. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("pump-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/pump-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/pump-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the pump..

This pretrained image model uses a Nyckel-created dataset and has 8 labels, including Excellent Condition, Fair Condition, Good Condition, New Condition, Okay Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the pump.).

Whether you're just curious or building pump conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify pump conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

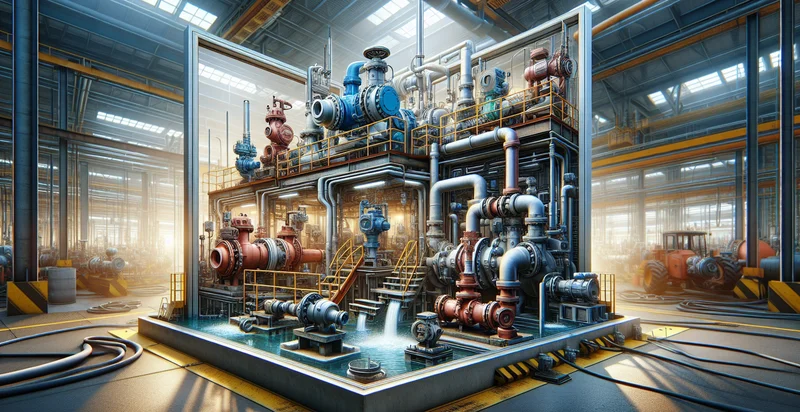

- Predictive Maintenance: This use case involves using the false image classification function to identify abnormal pump conditions that may indicate impending failures. By analyzing images from operational pumps, the system can proactively alert maintenance teams, reducing downtime and maintenance costs.

- Quality Control in Manufacturing: In a manufacturing setting, this function can verify that pump components are free from defects by classifying images of the parts. By ensuring all components meet quality standards, businesses can prevent issues in assembly and improve overall product reliability.

- Remote Monitoring: Companies utilizing remote monitoring systems can leverage this function to classify pump conditions visually transmitted from remote locations. This allows operators to assess the status of pumps without physical presence, enabling timely interventions and improving operational efficiency.

- Training for Operators: The false image classification function can be used in training programs for new operators by providing examples of both normal and faulty pump conditions. This helps personnel recognize signs of trouble quickly, enhancing safety and operational competence.

- Regulatory Compliance Verification: Businesses in regulated industries can use this function for ensuring compliance with safety standards. By systematically classifying pump conditions via images, companies can document proper functioning equipment, aiding in audits and regulatory reporting.

- Inventory Management: This use case pertains to the classification of spare pumps and parts based on their conditions, using image analysis to categorize them as usable or requiring refurbishment. This helps optimize inventory management by ensuring necessary parts are on hand while reducing holding costs for damaged ones.

- Customer Support Improvement: The image classification function can be integrated into customer support systems, allowing customers to submit images of their pump conditions for diagnosis. Automated classification could expedite service requests and troubleshooting, leading to enhanced customer satisfaction and quicker resolution times.