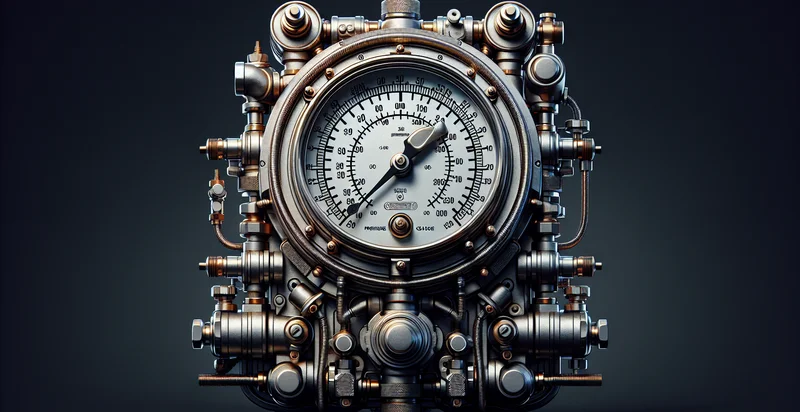

Identify pressure gauge conditions

using AI

Below is a free classifier to identify pressure gauge conditions. Just upload your image, and our AI will predict the current pressure gauge conditions - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("pressure-gauge-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/pressure-gauge-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/pressure-gauge-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the current pressure gauge conditions.

This pretrained image model uses a Nyckel-created dataset and has 15 labels, including Average Condition, Damaged, Excellent Condition, Excessively Worn, Fair Condition, Functional, Good Condition, Moderately Worn, Needs Repair and New.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the current pressure gauge conditions).

Whether you're just curious or building pressure gauge conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify pressure gauge conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: This use case involves using false image classification to identify pressure gauges that are malfunctioning or showing abnormal conditions. By analyzing images from operational environments, businesses can predict failures before they occur, minimizing downtime and maintenance costs.

- Quality Control in Manufacturing: In manufacturing processes involving pressure gauges, this function can help identify faulty gauges that may compromise product quality. By implementing this system on production lines, manufacturers can ensure that only accurate gauges are used, maintaining high-quality standards.

- Automation in Industrial Settings: The false image classification function can be integrated into an automated system that continuously monitors pressure gauges in real-time. This enhances operational efficiency by reducing the need for manual checks and allowing for quick responses to any detected anomalies.

- Safety Compliance Monitoring: Safety regulations often require regular monitoring of pressure gauges in industries such as oil and gas. This function can automate compliance checks by identifying gauges that may not be operating within safe limits, thus improving workplace safety.

- Remote Monitoring Solutions: For industries relying on remote operations, this classification function can allow for effective monitoring of pressure gauges from afar. By filtering out false images, operators can focus on genuine alerts, making remote management more efficient.

- Enhanced Training Tools: The false image classification function can serve as a training tool for new employees in industries that utilize pressure gauges. By simulating various conditions and teaching workers to identify genuine gauge readings versus erroneous signals, businesses can enhance their training programs.

- Resource Allocation Optimization: By identifying pressure gauges that are underperforming, businesses can allocate resources more effectively. This can help in planning maintenance schedules, purchasing new equipment, or reallocating workforce efforts to ensure that operational efficiency is maximized.