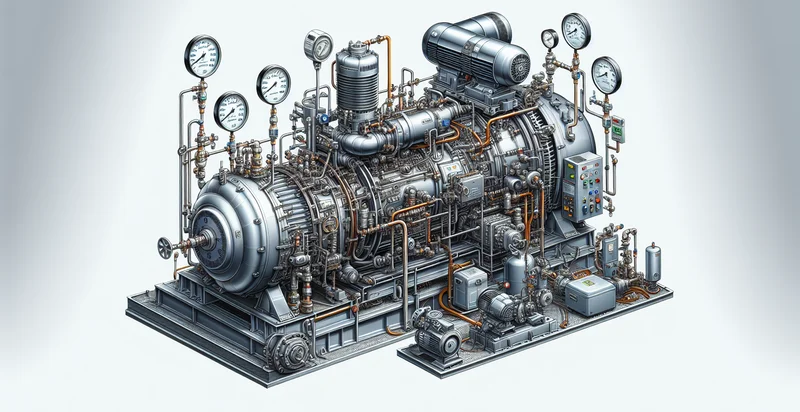

Identify pneumatic system conditions

using AI

Below is a free classifier to identify pneumatic system conditions. Just upload your image, and our AI will predict the operational status of various pneumatic system components - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("pneumatic-system-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/pneumatic-system-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/pneumatic-system-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the operational status of various pneumatic system components.

This pretrained image model uses a Nyckel-created dataset and has 6 labels, including Excellent Condition, Fair Condition, Good Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the operational status of various pneumatic system components).

Whether you're just curious or building pneumatic system conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify pneumatic system conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

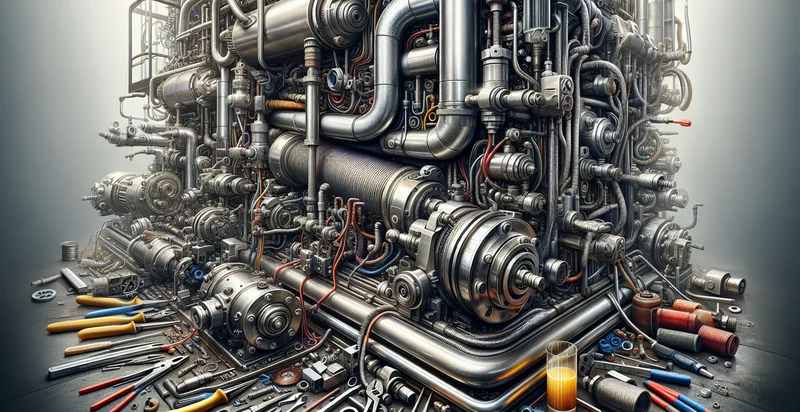

- Predictive Maintenance: This function can be integrated into a predictive maintenance system for pneumatic machinery, where it identifies potential failures or anomalies based on sensor data. By detecting unusual patterns, it helps prevent unexpected downtime and reduces maintenance costs.

- Quality Control in Manufacturing: In manufacturing environments that utilize pneumatic systems, this function can be employed to monitor the performance of pneumatic equipment. Ensuring that systems operate within specified parameters helps maintain product quality and reduces waste.

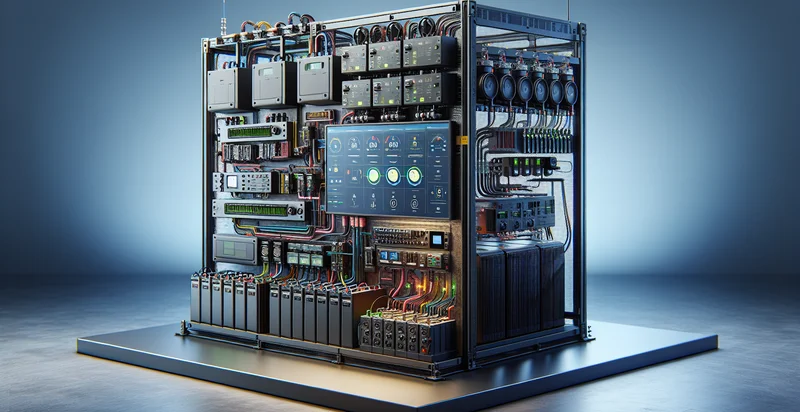

- Energy Consumption Optimization: The false image classification function can analyze the operational efficiency of pneumatic systems to identify energy-consuming anomalies. By addressing inefficiencies, companies can significantly lower their energy consumption and operational costs.

- Safety Monitoring: Integration of this classification function into pneumatic system monitoring can enhance workplace safety. It enables early detection of hazardous conditions, allowing for timely interventions that protect workforce safety and comply with regulatory standards.

- Process Automation: In automated settings, the function can facilitate real-time decision-making about pneumatic system operations. By rapidly classifying system conditions, it can trigger automated responses or adjustments, improving overall system reliability and performance.

- Data-Driven Insights: Companies can leverage this function to gather insights on the operational history of pneumatic systems. By analyzing the classifications, organizations can make more informed decisions regarding upgrades, replacements, or design improvements based on detected trends.

- Remote Monitoring Solutions: The false image classification function enables remote monitoring of pneumatic systems across multiple locations. By providing stakeholders with real-time condition assessments, it supports proactive management and maintenance strategies without the need for on-site visits.