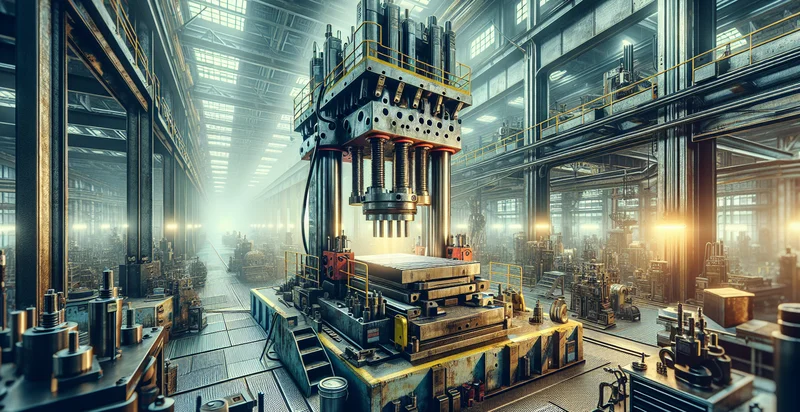

Identify plasma cutter conditions

using AI

Below is a free classifier to identify plasma cutter conditions. Just upload your image, and our AI will predict the appropriate cutting conditions for different materials - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("plasma-cutter-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/plasma-cutter-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/plasma-cutter-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the appropriate cutting conditions for different materials.

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Damaged, Excellent Condition, Fair Condition, Functional But Outdated, Good Condition, Like New, Needs Repair, Operational But Worn, Poor Condition and Regular Maintenance Needed.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the appropriate cutting conditions for different materials).

Whether you're just curious or building plasma cutter conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify plasma cutter conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control Monitoring: This function can be implemented in manufacturing facilities to automatically identify and flag non-compliant plasma cutting conditions that may lead to substandard products. By integrating it with manufacturing equipment, companies can ensure that only high-quality parts go through the production process, minimizing waste and rework.

- Predictive Maintenance: By analyzing plasma cutter conditions, this function can help predict potential equipment failures before they occur. By identifying abnormal operating conditions, maintenance teams can proactively address issues, thereby reducing downtime and minimizing costly repairs.

- Operator Training Enhancement: This image classification function can be used to enhance training programs for plasma cutter operators. By providing them with real-time feedback on their cutting conditions, new employees can learn to recognize optimal operational practices and avoid common mistakes.

- Safety Compliance Verification: In environments where plasma cutting is prevalent, ensuring safety compliance is critical. The function can identify unsafe operational conditions in real-time, alerting operators and safety personnel to address them immediately, thereby reducing the risk of accidents in the workplace.

- Remote Monitoring Solutions: Manufacturers can utilize this function for remote monitoring of plasma cutting equipment, enabling operators to keep an eye on conditions from afar. This is particularly beneficial for facilities that operate in hazardous environments, allowing for better resource management without compromising safety.

- Data Analytics for Process Optimization: By collecting data on cutting conditions through this classification function, companies can conduct in-depth analyses to optimize their cutting processes. The insights gained can lead to improved efficiency, reduced operational costs, and enhanced overall productivity.

- Regulatory Compliance Auditing: This function can be integrated into quality assurance systems to verify adherence to industry standards and regulatory requirements for plasma cutting operations. By automatically identifying non-compliance, companies can streamline their auditing processes and ensure they meet all necessary regulations.