Identify part conditions

using AI

Below is a free classifier to identify part conditions. Just upload your image, and our AI will predict the conditions of different machine parts - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("part-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/part-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/part-conditions/invoke

How this classifier works

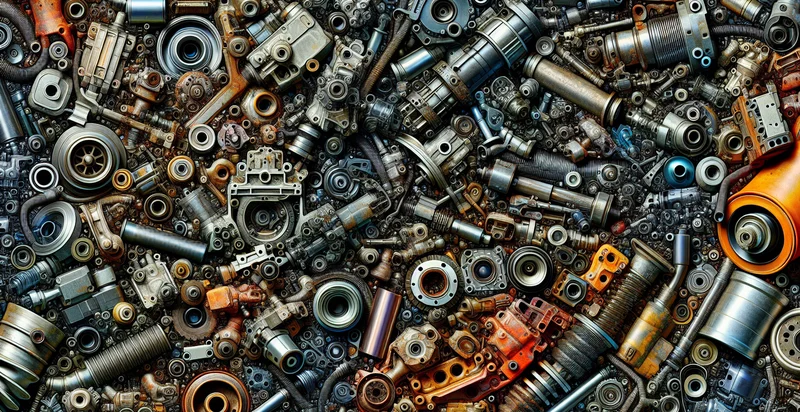

To start, upload your image. Our AI tool will then predict the conditions of different machine parts.

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Damaged, Functional, Like New, New, Non-Functional, Opened, Refurbished, Unopened, Used and Worn.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the conditions of different machine parts).

Whether you're just curious or building part conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify part conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: This use case involves using the false image classification function to identify and classify defective parts during the manufacturing process. By analyzing images of parts, the system can automatically flag items that do not meet quality standards, reducing human error and increasing efficiency.

- Automotive Safety Inspection: In the automotive industry, this function can be employed to assess the condition of critical components such as brakes and tires. By identifying images of worn or damaged parts, companies can ensure better maintenance and enhance vehicle safety for consumers.

- Inventory Management for Retail: Retailers can utilize the false image classification function to evaluate the condition of products on shelves or in storage. By identifying damaged packaging or expired goods, businesses can maintain their inventory standards, leading to improved customer satisfaction and reduced waste.

- Robotics for Automated Repairs: Integrating this function into robotics systems for automated repair facilities can enable robots to classify and identify faulty components in machinery. This allows for quicker repairs and maintenance, thereby minimizing downtime and operational costs.

- E-commerce Product Returns: Online retailers can leverage the image classification function to assess the conditions of returned products. By automatically classifying items based on their condition—such as used, damaged, or like-new—companies can streamline the return process and determine appropriate restocking methods.

- Construction Equipment Monitoring: Construction firms can implement this function to regularly monitor the condition of heavy equipment through image analysis. By classifying parts for wear and tear, the system facilitates proactive maintenance, thereby extending equipment lifespan and improving safety on job sites.

- Medical Device Compliance: In the healthcare sector, this functionality can be utilized to ensure medical devices are in satisfactory condition before use. By classifying images of devices that might be damaged or malfunctioning, healthcare organizations can enhance patient safety and ensure compliance with regulatory standards.