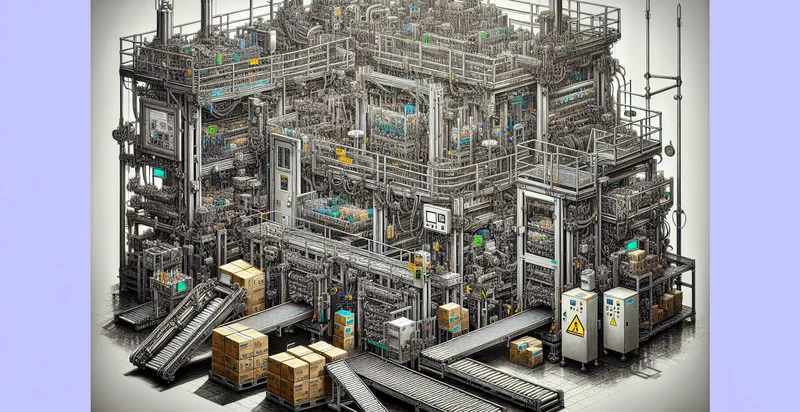

Identify palletizer conditions

using AI

Below is a free classifier to identify palletizer conditions. Just upload your image, and our AI will predict the optimal palletizing conditions for different products - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("palletizer-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/palletizer-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/palletizer-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal palletizing conditions for different products.

This pretrained image model uses a Nyckel-created dataset and has 6 labels, including Fair Condition, Good Condition, Like New Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal palletizing conditions for different products).

Whether you're just curious or building palletizer conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify palletizer conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control Validation: This function can be used in manufacturing environments to verify that the conditions of pallets are correct before they are processed. By identifying false images of pallet conditions, businesses can significantly reduce the number of defective products that make it to the shipping stage.

- Automated Sorting Systems: Integrating this classifier into automated sorting systems can improve efficiency by ensuring that only pallets meeting specific criteria are sent to designated areas. The function helps in real-time assessment, enabling quick adjustments to the sorting process.

- Supply Chain Optimization: This identification system assists businesses in tracking and managing inventory by monitoring pallet conditions throughout the supply chain. By recognizing faulty pallets, companies can take corrective actions, minimizing delays and ensuring a smoother operation.

- Preventative Maintenance Programs: Utilizing this function can contribute to preventative maintenance by identifying pallets that may lead to equipment wear or malfunction. By proactively addressing issues, businesses can lower maintenance costs and reduce downtime.

- Safety Compliance Monitoring: This image classifier can be instrumental in ensuring that pallets adhere to workplace safety standards. By detecting incorrectly stacked or damaged pallets, facilities can mitigate risks and enhance overall workplace safety.

- Predictive Analytics: The ability to classify pallet conditions can feed into predictive analytics models, helping businesses anticipate production or delivery delays. By analyzing patterns in false classifications, companies can fine-tune their logistics and improve service levels.

- Training and Development: Organizations can use the classifier to develop training programs for employees on best practices for pallet loading and maintenance. By providing accurate feedback on pallet conditions, employees can better understand how to prevent issues and increase operational efficiency.