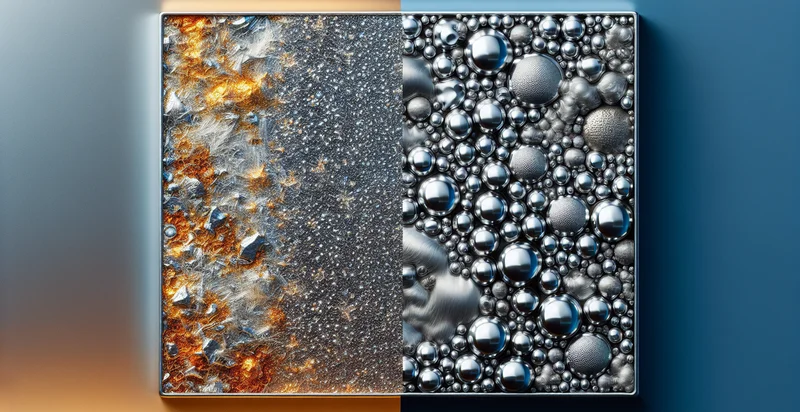

Identify painted vs unpainted

using AI

Below is a free classifier to identify painted vs unpainted. Just upload your image, and our AI will predict if an object is painted or unpainted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("painted-vs-unpainted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/painted-vs-unpainted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/painted-vs-unpainted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if an object is painted or unpainted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Painted and Unpainted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if an object is painted or unpainted).

Whether you're just curious or building painted vs unpainted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify painted vs unpainted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: In manufacturing plants, the painted vs unpainted identifier can be used to ensure that components receive the correct finishing process. By automating inspections, companies can reduce the risk of defects and ensure compliance with quality standards, resulting in cost savings and improved product reliability.

- Automotive Inspection: Automotive manufacturers can utilize this classification function to quickly assess whether vehicle parts have been adequately painted before assembly. This guarantees that all components meet aesthetic and protective standards, decreasing the likelihood of corrosion and enhancing the vehicle's overall lifespan.

- Paint Supply Chain Management: Paint companies can utilize the identifier to track inventory levels effectively by recognizing which products are unpainted and need treatment. This aids in optimizing production scheduling and reducing waste, ultimately improving operational efficiency and responsiveness to market demands.

- Home Renovation Services: Home improvement contractors can use the painted vs unpainted identification tool to accurately assess the surface states of various structures, helping estimate costs and labor for projects. This capability enhances their proposals and allows clients to make informed decisions about their renovation plans.

- Insurance Claims Processing: Insurance companies can deploy this technology to facilitate faster claims processing for property damage. By accurately determining whether a surface is painted or unpainted, assessors can more effectively gauge the extent of damage and expedite settlements for repair works.

- Environmental Compliance: Companies dealing with hazardous materials can leverage this classification to ensure that certain surfaces are treated with protective coatings, minimizing environmental risks. By monitoring compliance with environmental regulations, organizations can avoid penalties and enhance their sustainability efforts.

- Art Restoration Projects: Museums and art restorers can utilize the painted vs unpainted identifier to assess the condition of artworks and artifacts. This understanding helps them make informed decisions on restoration techniques, ensuring that original materials are preserved and enhancing the integrity of historical pieces.