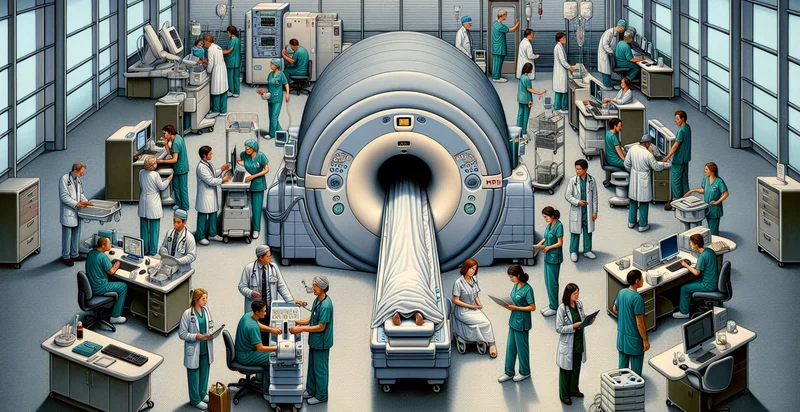

Identify mri machine conditions

using AI

Below is a free classifier to identify mri machine conditions. Just upload your image, and our AI will predict the condition of the MRI machine. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("mri-machine-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/mri-machine-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/mri-machine-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the MRI machine..

This pretrained image model uses a Nyckel-created dataset and has 4 labels, including Excellent Condition, Fair Condition, Good Condition and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the MRI machine.).

Whether you're just curious or building mri machine conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify mri machine conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Preventive Maintenance Scheduling: The MRI machine conditions identifier can be integrated into maintenance management systems to flag potential issues before they cause machine failure. By analyzing real-time data and identifying abnormal patterns, healthcare facilities can schedule preventive maintenance, extending the lifespan of their equipment and reducing downtime.

- Quality Assurance in Imaging: By continuously monitoring MRI machine conditions, this function can ensure consistent image quality by alerting technicians to any degradation in performance. Enhanced quality assurance leads to more accurate diagnoses and better patient outcomes.

- Resource Allocation Optimization: Hospitals can leverage the MRI machine conditions identifier to optimize the utilization of resources. By understanding which machines require maintenance or are at risk, facilities can better allocate technicians, decreasing wait times for patients and improving overall operational efficiency.

- Compliance and Regulatory Reporting: The identifier can aid healthcare providers in maintaining compliance with regulatory standards related to medical imaging equipment. By generating reports on machine conditions, facilities can demonstrate adherence to safety and quality regulations, thereby avoiding potential penalties.

- Data-Driven Decision Making: Integrating the MRI machine conditions identifier with an analytics platform enables healthcare administrators to make informed decisions regarding equipment procurement and upgrades. By analyzing condition data over time, administrators can prioritize financial investments in MRI machines that deliver the best performance.

- Enhanced Patient Safety: By identifying faulty conditions in MRI machines in real-time, this function can prevent potentially dangerous situations for patients and staff. Prompt interventions can mitigate risks, ensuring a safer imaging environment for patients undergoing scans.

- Training and Education: The MRI machine conditions identifier can serve as an educational tool for radiology technicians and technicians in training. By reviewing case studies related to detected faults and the subsequent actions taken, they can gain practical insights into machine maintenance and troubleshooting.