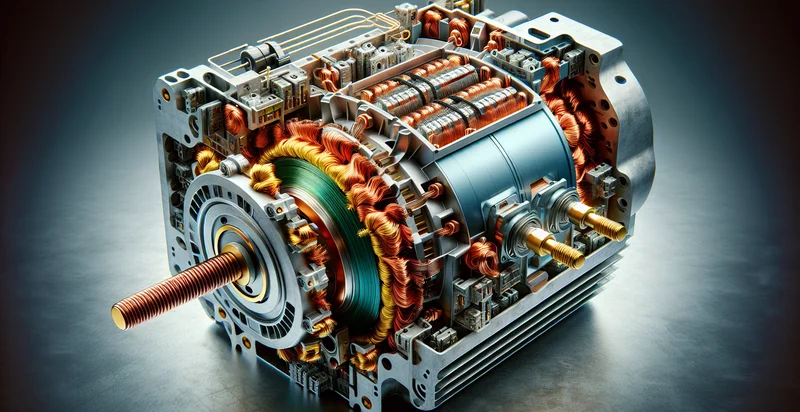

Identify motor conditions

using AI

Below is a free classifier to identify motor conditions. Just upload your image, and our AI will predict what motor conditions are present - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("motor-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/motor-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/motor-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict what motor conditions are present.

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Damaged Condition, Excellent Condition, Fair Condition, Good Condition, Misaligned Condition, Non Operational Condition, Operational Condition, Poor Condition, Repaired Condition and Worn Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around what motor conditions are present).

Whether you're just curious or building motor conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify motor conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: The motor conditions identifier can be employed in manufacturing settings to predict when a motor is likely to fail or require maintenance. By analyzing real-time images and classifying motor conditions, businesses can implement maintenance schedules that reduce downtime and save on repair costs.

- Quality Control in Production: In assembly lines, the function can be integrated into quality control processes to inspect motors and ensure they meet specified conditions before being sent to customers. Automated image classification can help detect defects or anomalies that might affect motor performance.

- Supply Chain Optimization: Companies can use the identifier to classify the condition of motors received from suppliers during the procurement process. This ensures that only motors that meet operational standards are accepted, reducing the risk of incorporating faulty parts into production.

- Warranty Analysis: The ability to classify motor conditions can assist businesses in analyzing warranty claims on electric motors. By assessing the condition of returned motors through images, companies can identify trends in failures and adjust warranty terms accordingly.

- End-of-Life Assessment: The motor conditions identifier can be used to assess motors nearing the end of their operational life in industrial settings. By determining the state of deterioration through image analysis, companies can make informed decisions on replacements and budgeting for new motors.

- Safety Compliance Verification: In industries where motor safety is critical, this function can help verify compliance with safety standards. By regularly classifying motor conditions, organizations can ensure that motors are safe to operate and minimize risks associated with faulty equipment.

- Asset Tracking and Management: Businesses can implement the motor conditions identifier in asset management systems to maintain records of motor conditions over time. This can provide valuable insights for tracking performance and planning upgrades, ensuring that assets are managed efficiently.