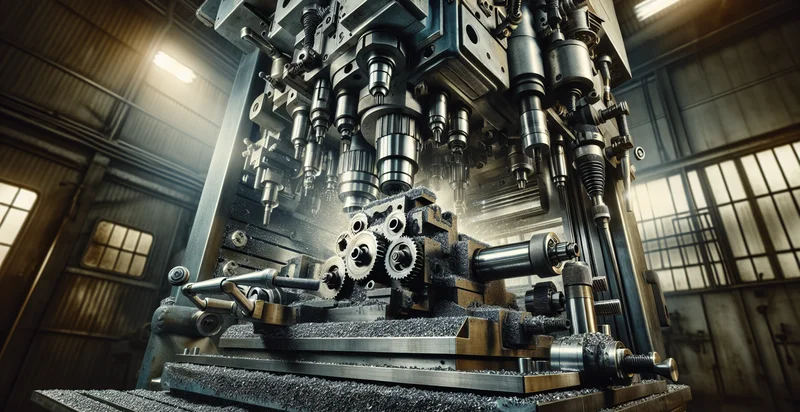

Identify milling machine conditions

using AI

Below is a free classifier to identify milling machine conditions. Just upload your image, and our AI will predict the operational status of milling machines under various conditions - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("milling-machine-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/milling-machine-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/milling-machine-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the operational status of milling machines under various conditions.

This pretrained image model uses a Nyckel-created dataset and has 13 labels, including Excellent Condition, Fair Condition, Good Condition, High Wear And Tear, Minimal Wear And Tear, Needs Repair, Not Operational, Operational, Poor Condition and Recently Serviced.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the operational status of milling machines under various conditions).

Whether you're just curious or building milling machine conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify milling machine conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: The false image classification function can be used to identify the condition of milling machines in real-time by analyzing images of their components. This helps in predicting potential failures, allowing for timely maintenance and reducing unplanned downtime.

- Quality Control: By classifying images of machined parts, the system can detect defects or abnormalities in the milling process. This ensures that only parts that meet quality standards move further down the production line, improving overall product quality.

- Safety Compliance Monitoring: The function can monitor the condition of milling machines to ensure they are functioning within safety norms. Detecting signs of wear or damage through image classification helps maintain workplace safety and compliance with regulations.

- Operator Training: Utilizing images of both proper and improper milling machine conditions, the system can serve as a training tool for new operators. By providing examples of classifications, trainees can better understand how to identify potential issues during their work.

- Inventory Management: The identification of milling machine conditions through image classification can assist in managing spare parts inventory. By predicting when specific parts are likely to fail, businesses can optimize inventory levels and reduce carrying costs.

- Performance Benchmarking: The function can analyze images over time to compare the performance of different milling machines. By identifying patterns in conditions, companies can benchmark machines and make data-driven decisions for future purchases or upgrades.

- Remote Monitoring: This classification system can be integrated with IoT devices for remote monitoring of milling machines. By continuously analyzing images sent from machine locations, businesses can ensure optimal operation and immediately respond to any issues that arise.