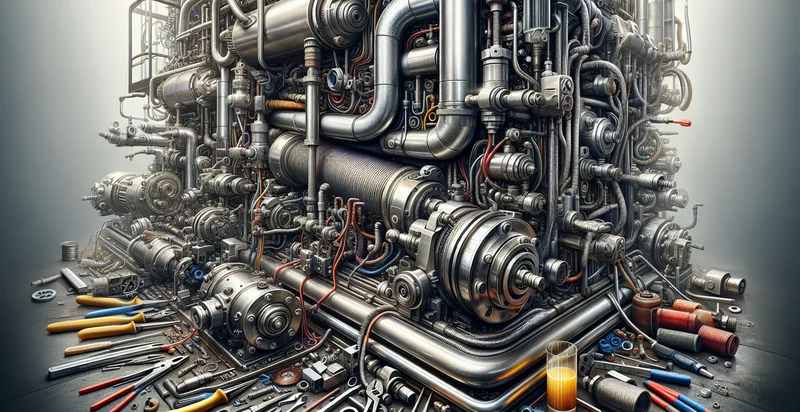

Identify manufacturing robot conditions

using AI

Below is a free classifier to identify manufacturing robot conditions. Just upload your image, and our AI will predict the appropriate operating conditions for manufacturing robots - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("manufacturing-robot-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/manufacturing-robot-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/manufacturing-robot-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the appropriate operating conditions for manufacturing robots.

This pretrained image model uses a Nyckel-created dataset and has 9 labels, including Defective Condition, Excellent Condition, Fair Condition, Good Condition, Non Operational Condition, Operational Condition, Poor Condition, Upgraded Condition and Very Good Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the appropriate operating conditions for manufacturing robots).

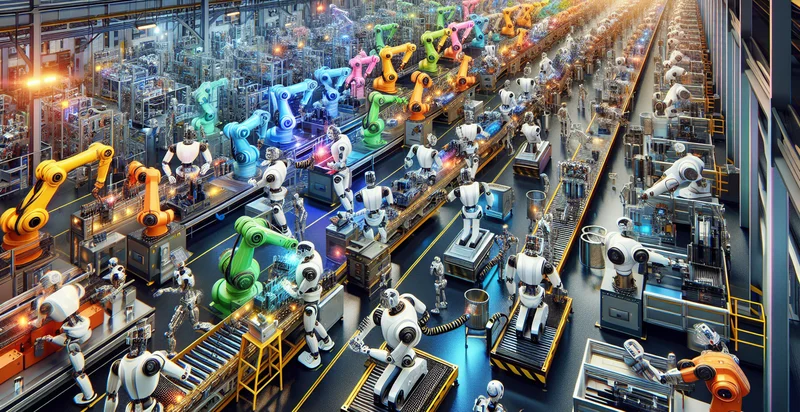

Whether you're just curious or building manufacturing robot conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify manufacturing robot conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Fault Detection: Implement the image classification function to automatically detect faults in robotic components during manufacturing processes. By identifying images of damaged or misaligned parts, the system can trigger alerts for maintenance, reducing downtime and enhancing operational efficiency.

- Quality Assurance: Utilize the image classification function to ascertain the condition of products produced by robots. By classifying images as either compliant or non-compliant, manufacturers can ensure that only products meeting quality standards proceed to the next stage of production.

- Predictive Maintenance: Integrate the function into predictive maintenance systems to analyze the wear and tear of robotic machinery. Regularly classifying images of equipment can provide valuable data for predicting failures before they occur, minimizing operational interruptions.

- Safety Compliance Monitoring: Employ the image classification function to verify that manufacturing robots are operating within defined safety conditions. By assessing images related to safety features, the system can ensure adherence to regulations, reducing the risk of accidents.

- Performance Analytics: Use the image classification function to monitor and analyze the performance conditions of manufacturing robots over time. By classifying images based on various performance metrics, businesses can gain insights into operational trends and areas for improvement.

- Training and Calibration: Leverage the classification function to assist in the calibration of robotic systems by providing feedback on their operational conditions. The system can classify images of calibration results, helping technicians adjust robots for optimal performance.

- Remote Monitoring: Incorporate the image classification function into remote monitoring solutions for manufacturing facilities. The system can analyze real-time images from robots, allowing operators to classify conditions remotely and respond promptly to any issues that arise.