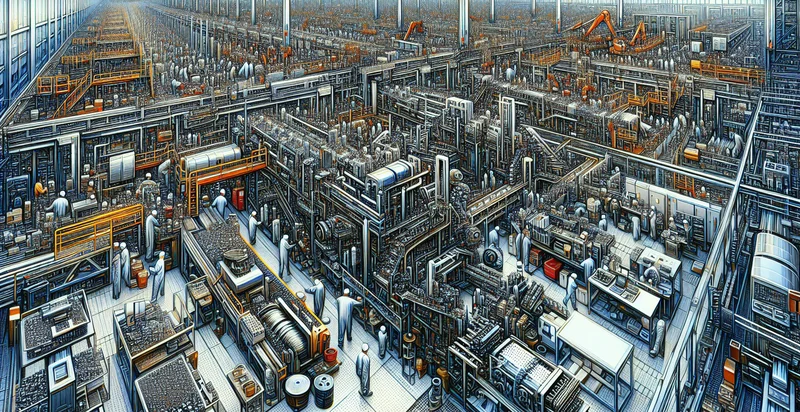

Identify manufacturing pattern

using AI

Below is a free classifier to identify manufacturing pattern. Just upload your image, and our AI will predict which manufacturing pattern it follows - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("manufacturing-pattern-identifier", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/manufacturing-pattern-identifier/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/manufacturing-pattern-identifier/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict which manufacturing pattern it follows.

This pretrained image model uses a Nyckel-created dataset and has 25 labels, including Assembly Line, Batch Production, Components Inspection, Conveyor Belt, Equipment Maintenance, Factory Workflow, Finished Goods Area, Industrial Automation, Job Shop and Just In Time Production.

We'll also show a confidence score (the higher the number, the more confident the AI model is around which manufacturing pattern it follows).

Whether you're just curious or building manufacturing pattern detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify manufacturing pattern at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control Enhancement: The manufacturing pattern identifier can be used in quality assurance processes to detect anomalies in production patterns. By identifying deviations from standard patterns, manufacturers can prevent defective products from reaching the market, thereby improving overall product quality and customer satisfaction.

- Predictive Maintenance: By analyzing manufacturing patterns, this function can help identify potential machinery failures before they occur. By flagging unusual patterns in machine performance, maintenance can be scheduled proactively, reducing downtime and maintenance costs.

- Process Optimization: The pattern identifier can analyze the efficiency of manufacturing workflows by recognizing patterns that lead to bottlenecks. This information allows managers to make data-driven decisions to streamline operations and improve throughput.

- Supply Chain Monitoring: By utilizing false image classification to assess production patterns, businesses can better monitor their supply chain. This helps in identifying delays, inefficiencies, or discrepancies in the supply chain, ensuring timely production and delivery.

- Customization of Product Designs: The manufacturing pattern identifier can analyze client preferences and production patterns, enabling companies to offer personalized product designs. Businesses can adjust their manufacturing processes based on detected trends, thus catering to specific customer demands.

- Compliance Verification: Companies can use the manufacturing pattern identifier to ensure compliance with industry regulations by detecting non-standard manufacturing practices. By identifying and addressing potential compliance issues early, companies can avoid penalties and enhance their reputation.

- Training and Skill Development: The function can be utilized to identify patterns in operator performance, pinpointing areas where additional training may be necessary. By recognizing skill gaps or inefficiencies in handling machines, organizations can tailor training programs to enhance workforce capabilities.