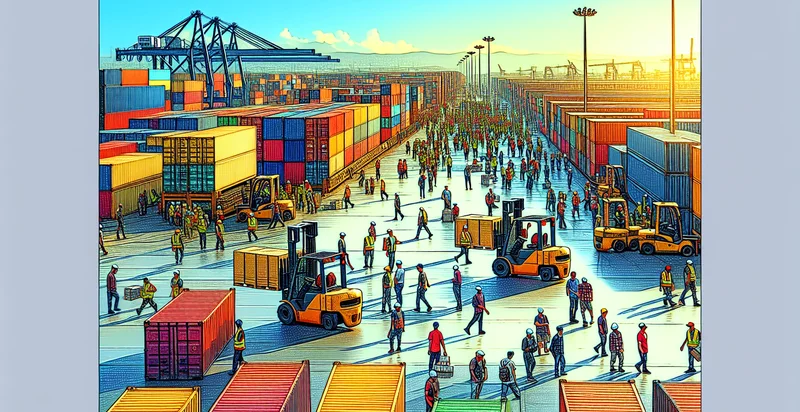

Identify loading dock configurations

using AI

Below is a free classifier to identify loading dock configurations. Just upload your image, and our AI will predict the optimal loading dock configuration for your facility - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("loading-dock-configurations", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/loading-dock-configurations/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/loading-dock-configurations/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal loading dock configuration for your facility.

This pretrained image model uses a Nyckel-created dataset and has 21 labels, including Angled, Compact, Container, Corner, Curved, Drive-Thru, Enclosed, Expandable, Flush and Hub.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal loading dock configuration for your facility).

Whether you're just curious or building loading dock configurations detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify loading dock configurations at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Inventory Management Optimization: By accurately classifying loading dock images, warehouses can optimize inventory placement based on real-time loading configurations. This aids in reducing loading times and improving overall warehouse efficiency.

- Safety Compliance Monitoring: The system can help identify incorrect loading dock configurations that may pose safety risks, such as obstructions in loading zones. This classification ensures compliance with safety regulations, reducing the likelihood of accidents.

- Streamlined Dock Scheduling: Analyzing loading dock images can help in classifying the current configurations to streamline dock scheduling. By predicting which docks are suitable for specific shipments, organizations can minimize wait times and enhance logistical planning.

- Automated Reporting for Audits: The function can classify and log loading dock configurations for periodic audits. This provides accurate data on loading process compliance and helps in identifying areas for improvement during internal reviews.

- Training and Simulation Programs: By using classified images of loading docks, companies can create realistic training simulations for staff. These simulations can help train employees on optimal loading practices and increase operational efficiency.

- Predictive Maintenance Alerts: Incorrect configurations may lead to equipment stress or malfunctions. By classifying images, the system can alert maintenance teams to potential issues before they escalate, minimizing downtime and repair costs.

- Enhanced Customer Experience: By ensuring that loading dock configurations are consistently correct, businesses can improve the timeliness of deliveries and pickups. This reliability enhances customer satisfaction and can provide a competitive advantage in logistics services.