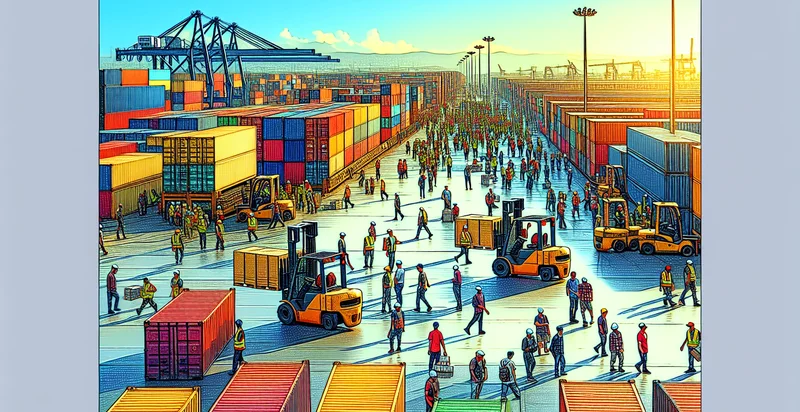

Identify loading dock conditions

using AI

Below is a free classifier to identify loading dock conditions. Just upload your image, and our AI will predict the loading dock conditions that may affect operations - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("loading-dock-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/loading-dock-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/loading-dock-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the loading dock conditions that may affect operations.

This pretrained image model uses a Nyckel-created dataset and has 4 labels, including Excellent Condition, Fair Condition, Good Condition and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the loading dock conditions that may affect operations).

Whether you're just curious or building loading dock conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify loading dock conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Safety Compliance Monitoring: This function can ensure that loading docks adhere to safety regulations by identifying unsafe conditions such as spills or obstacles. Regular monitoring can help prevent workplace accidents and enhance employee safety protocols.

- Operational Efficiency Analysis: By classifying loading dock conditions, businesses can identify bottlenecks caused by poor layout or clutter. This can help in redesigning workflows and optimizing loading dock efficiency, leading to reduced turnaround times and improved productivity.

- Predictive Maintenance Alerts: The function can detect early signs of wear or damage to loading dock equipment by classifying visual abnormalities. This proactive approach allows for timely maintenance, reducing the risk of equipment failure and costly downtimes.

- Inventory Management Optimization: Identifying conditions related to loading dock traffic can inform better inventory management strategies. When the dock is heavily used or occupied, businesses can adjust their inventory flow, reducing congestion and improving stock accuracy.

- Training and Development Support: The classification function can be used to train staff on recognizing unsafe or inefficient loading dock conditions. Real-life examples can enhance training programs, leading to a better-trained workforce that understands best practices for loading operations.

- Third-party Logistics (3PL) Performance Review: Companies utilizing 3PL services can employ the function to assess the operational conditions of their partners' loading docks. This insight helps in evaluating the performance of logistics partners and ensuring that they meet service level agreements.

- Cost Reduction Initiatives: By analyzing loading dock conditions, businesses can identify factors that lead to increased operational costs, such as energy inefficiencies or the need for additional labor during peak times. Addressing these issues can contribute to overall cost savings and improved profit margins.