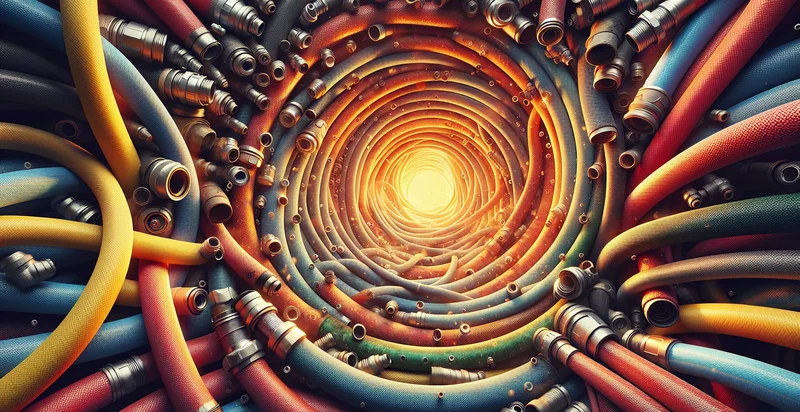

Identify loading conditions

using AI

Below is a free classifier to identify loading conditions. Just upload your image, and our AI will predict the appropriate loading conditions for optimal performance. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("loading-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/loading-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/loading-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the appropriate loading conditions for optimal performance..

This pretrained image model uses a Nyckel-created dataset and has 15 labels, including Crew Readiness, Environmental Factors, Equipment Condition, Facility Readiness, Gear Maintenance, Logistical Efficiency, Material Availability, Operational Capacity, Project Delays and Safety Compliance.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the appropriate loading conditions for optimal performance.).

Whether you're just curious or building loading conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify loading conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: The false image classification function can be utilized in manufacturing processes to identify loading conditions of products. By analyzing images of goods under various stress conditions, the system can flag products that may not meet quality standards, ensuring only safe and reliable products are shipped.

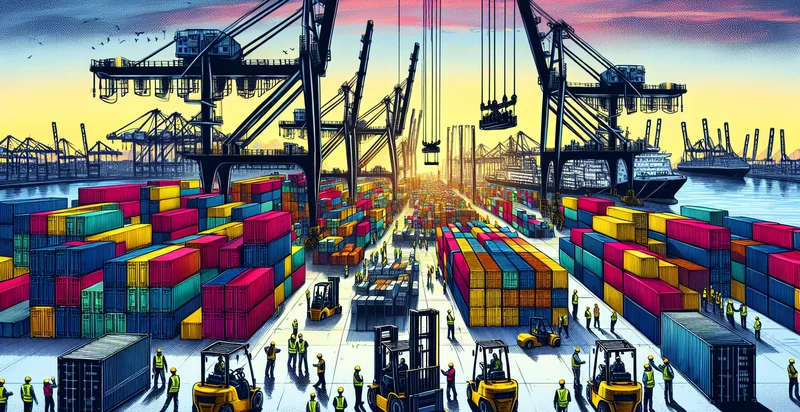

- Logistics and Transportation Monitoring: In the logistics industry, the function can assess whether cargo is loaded correctly in trucks or containers. By identifying incorrect loading conditions that could lead to damage, companies can minimize losses and enhance the safety of transportation.

- Agricultural Equipment Inspection: For agriculture, this function can help farmers determine if machinery is loaded correctly with produce or supplies during harvesting or transport. By ensuring optimal loading conditions, it can prevent equipment breakdowns and improve operational efficiency.

- Automotive Assembly Verification: Automotive manufacturers can use image classification to confirm that parts are loaded correctly onto assembly lines. By detecting misloading conditions in real-time, it reduces the chances of assembly errors and enhances overall production quality.

- Construction Site Safety Monitoring: Construction sites can benefit from this function by assessing if heavy materials are loaded safely on cranes or vehicles. By identifying improper loading conditions, it helps to prevent accidents and improve site safety for workers.

- Retail Inventory Management: Retailers can apply the function to monitor inventory loading in warehouses. By classifying images based on loading conditions, it can help ensure that products are stored correctly, reducing the risk of damage and facilitating easier retrieval.

- Recycling Facility Operations: In recycling facilities, the function can identify whether materials are loaded appropriately for processing. By detecting improper loading conditions, it can help optimize the sorting process, leading to improved efficiency and higher recycling rates.