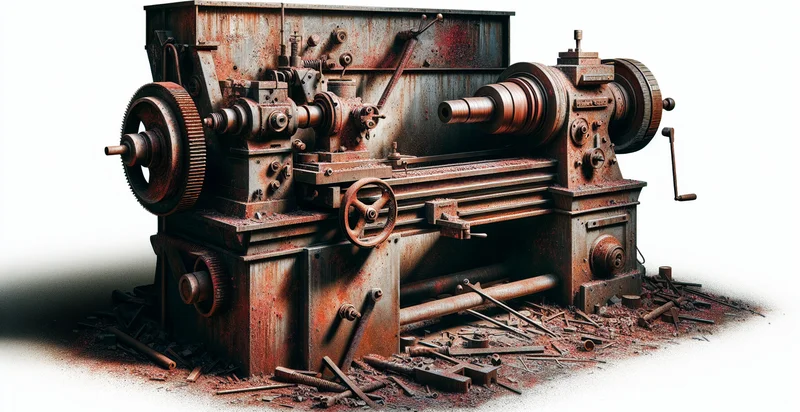

Identify lathe conditions

using AI

Below is a free classifier to identify lathe conditions. Just upload your image, and our AI will predict the optimal lathe conditions for different machining processes. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("lathe-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/lathe-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/lathe-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal lathe conditions for different machining processes..

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Excellent Condition, Fair Condition, Fully Operational, Good Condition, Heavily Used, Needs Repairs, Out Of Service, Poor Condition, Slightly Used and Well Maintained.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal lathe conditions for different machining processes.).

Whether you're just curious or building lathe conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify lathe conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Assurance in Manufacturing: This function can help manufacturers identify images that falsely depict lathe conditions, ensuring that output quality is maintained. By flagging incorrect representations of machining environments, companies can avoid defects caused by improper setups.

- Predictive Maintenance: The identifier can analyze lathe images to recognize early signs of wear and tear that may not be evident to human operators. By detecting false imaging of machine conditions, it helps schedule maintenance proactively, preventing costly downtime.

- Training and Simulation: In training environments, the function can differentiate between accurate and misleading images of lathe operations, improving the learning experience for trainees. This supports equipment operators by fostering skills in recognizing true machine conditions.

- Remote Monitoring: The function can be integrated into IoT systems for real-time analysis of lathe conditions. By ensuring the reliability of the visual data being sent from the lathe, it enhances remote troubleshooting efforts, making them more effective.

- Process Optimization: By assessing lathe condition images, the function can provide insights into operational inefficiencies stemming from incorrect setups. This analysis supports initiatives aimed at optimizing machining processes, leading to better resource utilization.

- Safety Compliance Verification: The identifier can assist safety officers in ensuring that images of lathes comply with regulatory standards. By identifying incorrectly displayed conditions, businesses can take corrective actions to enhance worker safety and compliance.

- Visual Documentation Management: This function can be employed to manage and verify visual documentation of lathe machinery over time. By identifying and correcting false imagery, companies can maintain accurate historical records for audits and operational improvements.