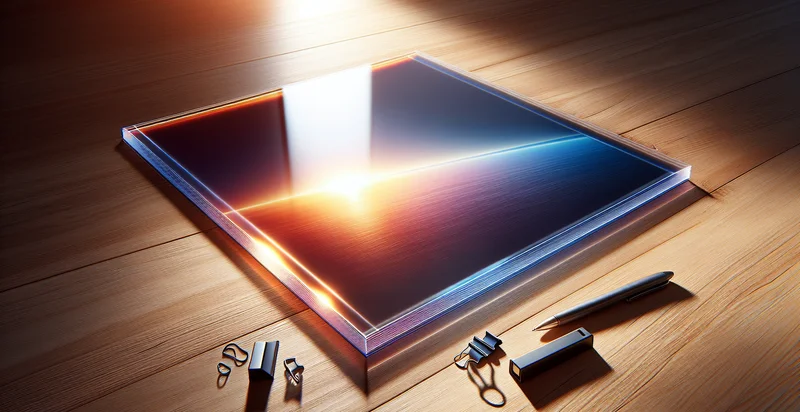

Identify lamination quality

using AI

Below is a free classifier to identify lamination quality. Just upload your image, and our AI will predict if the lamination quality is acceptable - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("lamination-quality", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/lamination-quality/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/lamination-quality/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the lamination quality is acceptable.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Compromised Lamination and Proper Lamination.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the lamination quality is acceptable).

Whether you're just curious or building lamination quality detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify lamination quality at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: The lamination quality identifier can be integrated into the production line to automatically assess the lamination of products in real-time. This ensures that only products meeting quality standards proceed to packaging, reducing waste and rework.

- Predictive Maintenance: By analyzing lamination quality over time, manufacturers can identify patterns that lead to defects. This proactive approach helps in scheduling maintenance for machinery before issues arise, minimizing downtime and costs.

- Supplier Quality Assurance: Businesses can use the lamination quality identifier to evaluate the quality of incoming materials from different suppliers. This allows procurement teams to maintain high standards and select suppliers based on consistent quality metrics.

- Product Development Feedback: The identifier can be employed in research and development to provide feedback on new lamination techniques or materials. This data-driven approach aids in optimizing product design for improved performance and durability.

- Compliance and Certification: Organizations can utilize the lamination quality identifier to ensure compliance with industry standards. This automated assessment capability can provide documentation for audits and certifications, establishing trust with customers and regulatory bodies.

- Training and Skill Development: The identifier can be used in training programs for operators by providing immediate feedback on their handling of lamination processes. This helps in quickly identifying gaps in skills and improving overall workforce competency.

- Customer Satisfaction and Returns Reduction: By implementing the lamination quality identifier, companies can reduce the likelihood of defects reaching customers. This leads to higher customer satisfaction, lower return rates, and enhanced brand reputation.