Identify laboratory centrifuge conditions

using AI

Below is a free classifier to identify laboratory centrifuge conditions. Just upload your image, and our AI will predict the optimal settings for operating a laboratory centrifuge under different conditions - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("laboratory-centrifuge-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/laboratory-centrifuge-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/laboratory-centrifuge-conditions/invoke

How this classifier works

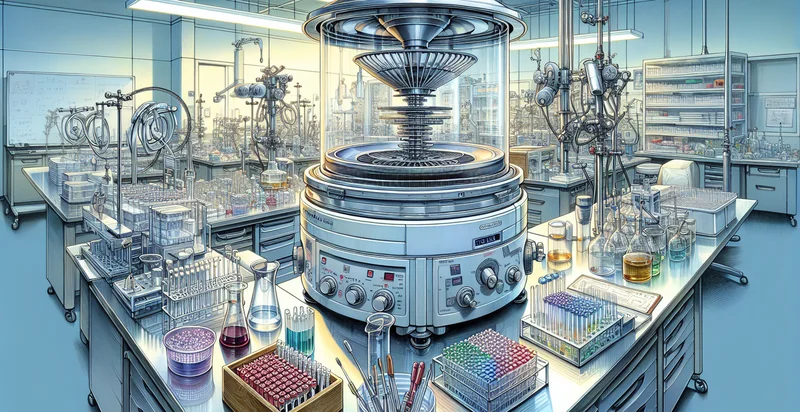

To start, upload your image. Our AI tool will then predict the optimal settings for operating a laboratory centrifuge under different conditions.

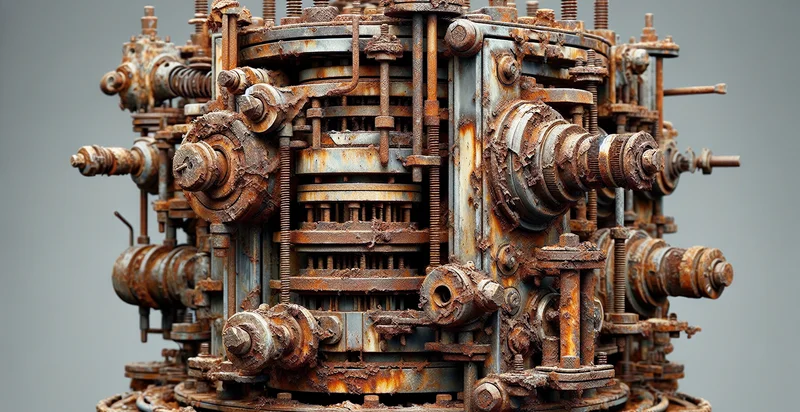

This pretrained image model uses a Nyckel-created dataset and has 5 labels, including Excellent Condition, Fair Condition, Good Condition, Moderate Condition and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal settings for operating a laboratory centrifuge under different conditions).

Whether you're just curious or building laboratory centrifuge conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify laboratory centrifuge conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Laboratories: This function can be utilized in laboratories to ensure that centrifuge images are correctly classified based on operational conditions. By identifying false images, the system helps maintain equipment integrity and enhances the accuracy of laboratory results.

- Training and Education: Educational institutions can implement this function within their training programs for laboratory technicians. It can help students learn to differentiate between false and genuine images of centrifuge conditions, improving their practical skills and knowledge.

- Preventive Maintenance Alerts: Facilities can use the identifier to monitor the conditions of centrifuges and automatically flag images that do not meet operational standards. This proactive approach enables timely maintenance, preventing costly breakdowns and ensuring continuous laboratory productivity.

- Regulatory Compliance: Laboratories can employ this function to comply with industry regulations by demonstrating that equipment is operating under validated conditions. Identifying false images and recording accurate operational data can provide timely evidence during audits or inspections.

- Research Data Integrity: Research institutions can leverage this function to ensure that visual data collected from centrifuge experiments is valid. By filtering out false images, researchers can maintain the integrity of their findings, ultimately promoting trust in their conclusions.

- Process Optimization: The function can aid in identifying inefficiencies in centrifuge operation processes by highlighting images that do not reflect standard conditions. Analyzing these anomalies can lead to optimization of protocols for better performance and enhanced throughput.

- Remote Monitoring Systems: This identifier can be integrated into remote monitoring systems for laboratories operating in multiple locations. By distinguishing between false and authentic centrifuge images, these systems can offer real-time alerts and insights, allowing for efficient resource management across sites.