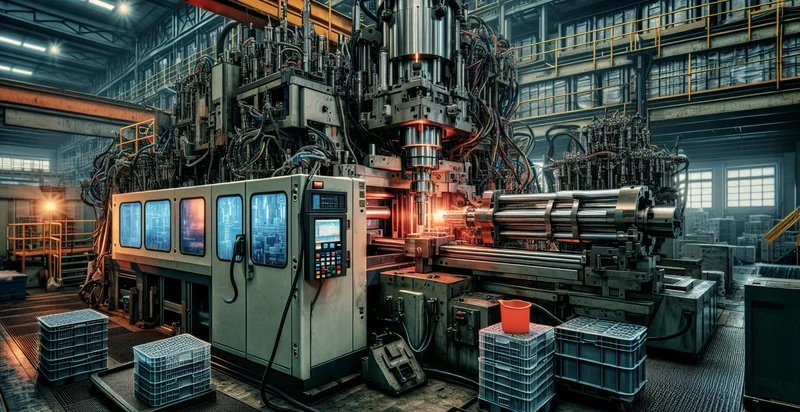

Identify injection molding machine conditions

using AI

Below is a free classifier to identify injection molding machine conditions. Just upload your image, and our AI will predict the optimal conditions for injection molding processes. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("injection-molding-machine-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/injection-molding-machine-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/injection-molding-machine-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the optimal conditions for injection molding processes..

This pretrained image model uses a Nyckel-created dataset and has 10 labels, including Average Condition, Damaged Condition, Excellent Condition, Fair Condition, Good Condition, Like New Condition, Poor Condition, Usable Condition, Very Poor Condition and Worn Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the optimal conditions for injection molding processes.).

Whether you're just curious or building injection molding machine conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify injection molding machine conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Condition Monitoring: This use case focuses on continuously monitoring the operational conditions of injection molding machines. By employing false image classification to identify abnormal operating conditions, manufacturers can proactively address issues before they lead to equipment failure, reducing downtime and maintenance costs.

- Quality Control: Utilizing the classification function to assess the conditions under which parts are produced can enhance quality control processes. By ensuring that machines operate within optimal parameters, manufacturers can reduce defects and improve product consistency.

- Predictive Maintenance: By analyzing images and classifying machine conditions, businesses can predict when maintenance is needed. This approach not only extends the lifespan of machines but also minimizes unexpected breakdowns by scheduling timely interventions.

- Training and Development: The classification system can be used as a training tool for operators and technicians. By exposing them to various machine conditions through simulated scenarios, employees can learn how to identify potential issues and respond effectively in real situations.

- Process Optimization: The false image classification can identify correlations between machine operating conditions and production efficiency. This insight allows engineers to adjust processes and parameters, leading to enhanced productivity and reduced material waste.

- Compliance and Reporting: In industries where compliance with standards is critical, this function can assist in documenting machine conditions during production. Accurate records support adherence to safety and quality regulations, making compliance reporting more straightforward and reliable.

- Enhanced Decision Support: By aggregating classified data on machine conditions, companies can leverage analytics for better decision-making. This can guide investments in new technology or machinery by providing insights into the performance and reliability of current systems under varied conditions.