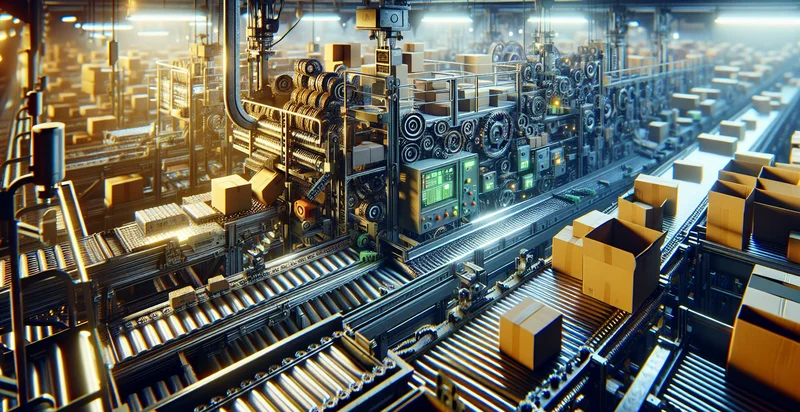

Identify industrial scale conditions

using AI

Below is a free classifier to identify industrial scale conditions. Just upload your image, and our AI will predict what category of industrial condition it is - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("industrial-scale-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/industrial-scale-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/industrial-scale-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict what category of industrial condition it is.

This pretrained image model uses a Nyckel-created dataset and has 7 labels, including Excellent Condition, Fair Condition, Good Condition, New Condition, Poor Condition, Very Good Condition and Very Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around what category of industrial condition it is).

Whether you're just curious or building industrial scale conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify industrial scale conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: This function can be applied in manufacturing environments to identify false positives in product defects. By distinguishing between real defects and false alarms, companies can reduce waste and improve production efficiency.

- Supply Chain Monitoring: In logistics, this function can detect false categorizations of goods under varying industrial conditions. This ensures that inventory records are accurate, enabling better resource allocation and minimizing costly errors in shipments.

- Predictive Maintenance: Industrial machinery often produces false readings due to varying operational conditions. This classification function can help discern these false signals, allowing for more accurate predictive maintenance schedules and reducing unexpected downtimes.

- Fault Detection in Equipment: By identifying false alarms in equipment performance, this function enhances the reliability of fault detection systems. This helps prevent unnecessary maintenance and allows for targeted interventions only when true faults occur.

- Safety Compliance Monitoring: Safety systems in industrial settings can misidentify hazardous conditions due to environmental factors. This function can help ensure that only genuine safety threats are raised, improving response times and overall workplace safety.

- Environmental Impact Assessments: In industries that have significant environmental monitoring needs, this classifier can help isolate genuine pollution signals from false positives. This leads to more accurate reporting and adherence to regulatory standards.

- Worker Health Monitoring: The function can be used to identify false readings in employee health monitoring systems due to changing industrial environments. This ensures that health-related alerts are based on true conditions, reducing stress and improving employee trust in monitoring systems.