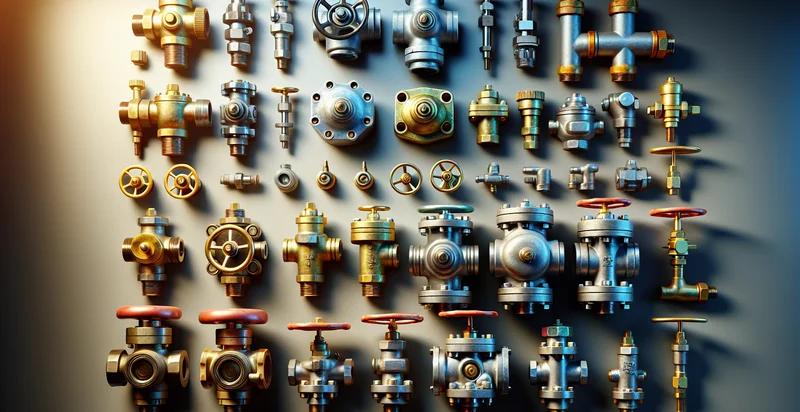

Identify if valve is rusted

using AI

Below is a free classifier to identify if valve is rusted. Just upload your image, and our AI will predict if the valve is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-valve-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-valve-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-valve-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the valve is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the valve is rusted).

Whether you're just curious or building if valve is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if valve is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Preventive Maintenance Alerts: The rust identification function can be integrated into maintenance management systems to generate alerts for scheduled inspections. This helps in proactively addressing rust issues before they lead to failures, ensuring minimal downtime in operations.

- Automated Condition Monitoring: Industrial facilities can leverage the rust identifier as part of their IoT systems for real-time condition monitoring of valves. By continuously assessing the condition of valves, businesses can ensure timely intervention based on data-driven insights.

- Quality Assurance in Manufacturing: Manufacturers can use the rust detection function in their quality control processes when inspecting valves. By automatically identifying rust, they can ensure only quality-assured products are shipped, improving overall customer satisfaction and reducing returns.

- Resource Allocation Optimization: With the rust identifier, companies can prioritize which valves need immediate attention, allowing for more efficient allocation of maintenance resources. This could lead to cost savings in both labor and materials by focusing efforts where they are most needed.

- Safety Compliance Reporting: The rust detection feature can aid companies in meeting safety regulations and compliance standards by keeping accurate records of equipment conditions. Regular reporting of rusted valves can help businesses avoid safety hazards and maintain compliance with industry standards.

- Risk Assessment for Asset Management: The identification of rusted valves can be used as part of a broader risk assessment strategy in asset management. By analyzing the frequency and locations of rust occurrences, companies can better understand potential risks and make informed decisions on asset replacements or upgrades.

- Training and Development Tools: The rust identification capability can be utilized in employee training programs within maintenance teams. By using real-world examples and scenarios, trainees can better understand how to diagnose valve conditions and respond appropriately to maintain system integrity.