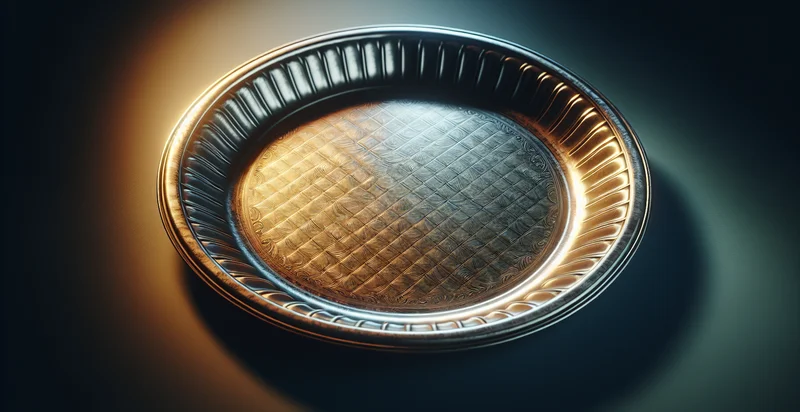

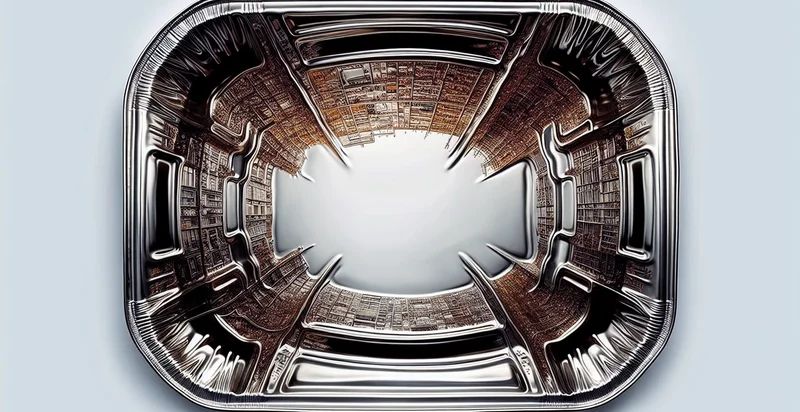

Identify if tray is upside down

using AI

Below is a free classifier to identify if tray is upside down. Just upload your image, and our AI will predict if the tray is upside down - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-tray-is-upside-down", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-tray-is-upside-down/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-tray-is-upside-down/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the tray is upside down.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Tray Is Right Side Up and Tray Is Upside Down.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the tray is upside down).

Whether you're just curious or building if tray is upside down detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if tray is upside down at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: In manufacturing settings where trays are used for parts or products, this image classification function can ensure that trays are consistently oriented correctly during assembly processes. By identifying upside-down trays, manufacturers can reduce defects and enhance product quality by preventing mishaps during the handling of components.

- Food Service Safety: In the food industry, ensuring trays are oriented correctly is crucial for food hygiene and safety. This function can help kitchen staff quickly identify and rectify improperly placed trays, minimizing the risk of contamination and maintaining compliance with health regulations.

- Automated Warehousing: In automated warehouses where trays hold products for sorting or storage, this function can optimize operations. By automatically detecting whether trays are upside down, logistics systems can streamline sorting processes, reduce manual inspection, and improve inventory accuracy.

- E-commerce Fulfillment Centers: In fulfillment centers for online retail, this technology can ensure that trays carrying products for shipping are correctly oriented. This minimizes the risk of items being damaged during the packing process, enhancing customer satisfaction and reducing returns.

- Healthcare Supply Management: In hospitals and clinics, correct orientation of trays used for medical supplies is critical for effective and safe operations. This classification function can help health workers quickly rectify any upside-down trays, ensuring that necessary supplies are easily accessible and ready for use during procedures.

- Restaurant Operations: In busy restaurant environments, maintaining the correct orientation of trays used for serving food can enhance service speed and efficiency. This function can be integrated into kitchen workflows to alert staff in real-time when an order tray is incorrectly positioned, helping to prevent delays and improve overall service quality.

- Educational Settings: In educational institutions that use trays for art projects or science experiments, this image classification can assist in organizing supplies. By identifying when trays are upside down, educators can ensure that students have quick access to materials, fostering a smoother learning experience without unnecessary disruptions.