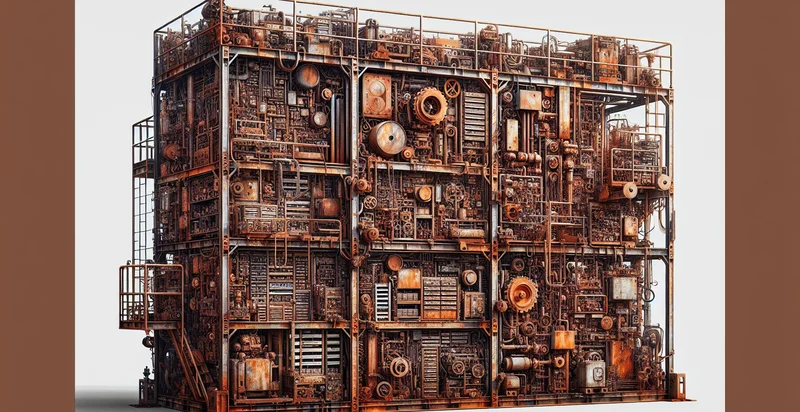

Identify if tool box is rusted

using AI

Below is a free classifier to identify if tool box is rusted. Just upload your image, and our AI will predict if the tool box is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-tool-box-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-tool-box-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-tool-box-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the tool box is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the tool box is rusted).

Whether you're just curious or building if tool box is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if tool box is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Maintenance Scheduling: This tool can automatically identify rusted toolbox equipment in a manufacturing setting. By flagging the items in need of maintenance, businesses can streamline their repair schedules and minimize equipment downtime.

- Inventory Management: Companies can utilize the rust identification function to manage and assess their inventory of tools and equipment. By keeping track of the condition of tools, businesses can prevent over-purchasing or under-utilization of resources.

- Safety Compliance: Regular monitoring for rust on toolboxes can help organizations comply with safety regulations. Identifying rust issues ensures that tools remain safe to use, thus mitigating the risk of accidents in the workplace.

- Quality Control: In industries where tool performance is critical, this function can assist in quality assurance processes. By regularly checking for rust, quality control teams can ensure that only well-maintained and reliable tools are used in production.

- Waste Reduction: The rust identification tool can help prevent premature disposal of equipment. By identifying rusting issues early, businesses can implement maintenance solutions that extend the lifespan of tools, reducing waste and operational costs.

- Cost Analysis: Businesses can analyze the frequency of rusted tools to better understand maintenance costs over time. This insight can help in budgeting for tool replacement and maintenance, leading to more informed financial decisions.

- Training & Development: This tool can be utilized in employee training programs to emphasize the importance of tool maintenance. By demonstrating how rust can impact tool performance, organizations can foster a culture of care and responsibility around equipment usage.