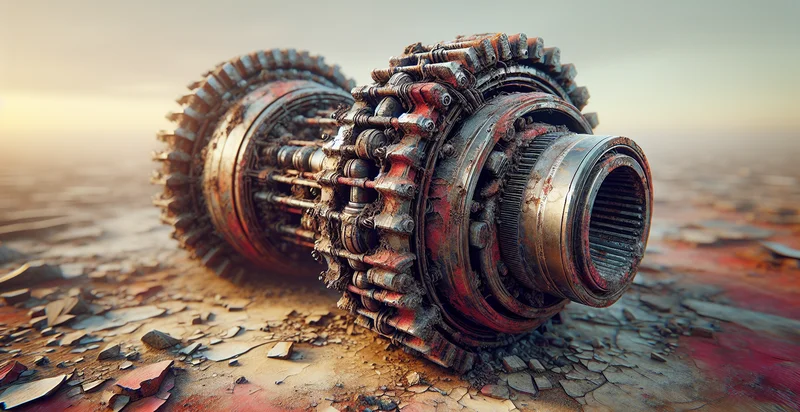

Identify if nut is rusted

using AI

Below is a free classifier to identify if nut is rusted. Just upload your image, and our AI will predict if the nut is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-nut-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-nut-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-nut-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the nut is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the nut is rusted).

Whether you're just curious or building if nut is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if nut is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Industrial Equipment Maintenance: The rust identification function can be integrated into predictive maintenance systems for industrial machinery. By identifying rust on nuts and bolts, maintenance teams can prioritize inspections and replace parts before they fail, reducing downtime and improving operational efficiency.

- Quality Control in Manufacturing: In manufacturing settings, this classification function can be utilized in quality control processes. Automated systems can scan and identify rusted nuts, allowing for real-time sorting and removal of defective products, ensuring only high-quality items are shipped to customers.

- Automotive Safety Inspections: Automotive service centers can employ this rust identification feature during vehicle inspections. By quickly identifying rusted nuts, technicians can recommend necessary repairs to ensure the safety and reliability of vehicles before they are returned to the owner.

- Home Inspection Services: Home inspectors can leverage this function to enhance their service offering. By identifying rust on nuts in critical areas (e.g., plumbing or structural components), inspectors can provide homeowners with detailed reports and remediation recommendations, increasing the value of their inspections.

- Construction Site Management: Project managers on construction sites can use the rust identifier to monitor the condition of fasteners used in structural assemblies. By regularly checking for rust, they can ensure compliance with safety standards and avoid structural failings due to degraded materials.

- Supply Chain Quality Assurance: Distribution centers can integrate this function to ensure the integrity of fasteners being shipped. Identifying rusted nuts during the logistics process can prevent damaged goods from reaching customers, maintaining brand reputation and reducing returns and replacements.

- Lifecycle Management of Equipment: Organizations can integrate this identifier into asset management systems to track the condition of fasteners over time. By monitoring and reporting frequent rust occurrences, they can inform better lifecycle management decisions, including replacements or preventive measures to extend equipment lifespan.