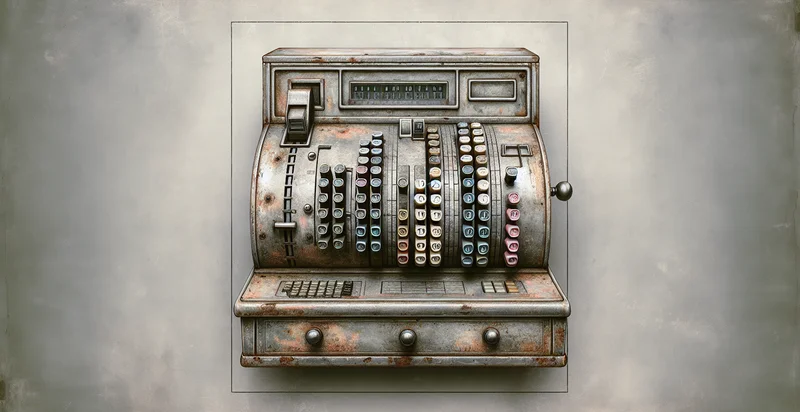

Identify if metal vise is rusted

using AI

Below is a free classifier to identify if metal vise is rusted. Just upload your image, and our AI will predict if the metal vise is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-metal-vise-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-metal-vise-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-metal-vise-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the metal vise is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the metal vise is rusted).

Whether you're just curious or building if metal vise is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if metal vise is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Maintenance Scheduling: This function can be utilized in industrial settings to automatically assess the condition of metal vises used in machinery. By identifying rusted vises, maintenance teams can schedule timely repairs or replacements, minimizing downtime and ensuring smooth operations.

- Quality Control in Manufacturing: In a manufacturing environment, this classification function can serve as a part of a quality control system. By detecting rusted metal vises, manufacturers can ensure that tools are in optimal condition, reducing defects in production and enhancing product quality.

- Asset Management: Equipment managers can leverage this function to evaluate the condition of tools over time. By systematically identifying rusted vises, they can maintain an accurate inventory of usable equipment and make informed investment decisions regarding replacements and upgrades.

- Safety Compliance: In workplaces where metal vises are heavily utilized, ensuring their integrity is critical for worker safety. This function can identify rusted vises that may pose safety risks, allowing for proactive measures to be taken before accidents occur.

- Vendor Quality Assurance: Suppliers of industrial tools can implement this image classification function to perform inspections on their inventory. By testing for rust, they can ensure that only high-quality vises are shipped to customers, thereby enhancing customer satisfaction and brand reputation.

- Preventive Maintenance Analytics: Organizations can use the rust detection capability as part of a broader preventive maintenance strategy. By analyzing data on rust occurrences, they can identify trends in tool degradation and optimize maintenance protocols accordingly.

- Environmental Monitoring: Companies in the manufacturing sector can employ this function to monitor equipment exposed to corrosive environments. Identifying rust early allows them to take corrective actions, which can lead to improved sustainability practices and reduced waste from prematurely discarded tools.