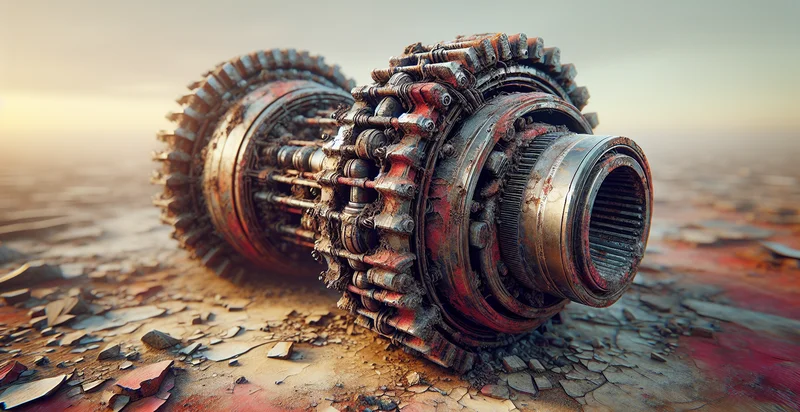

Identify if metal pulley is rusted

using AI

Below is a free classifier to identify if metal pulley is rusted. Just upload your image, and our AI will predict if the metal pulley is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-metal-pulley-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-metal-pulley-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-metal-pulley-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the metal pulley is rusted.

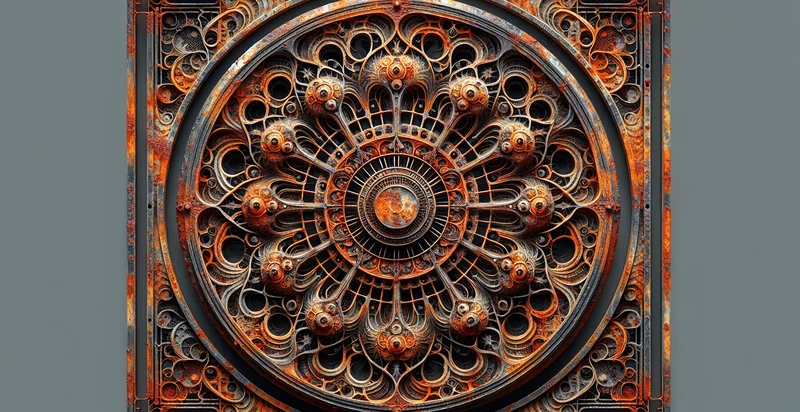

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the metal pulley is rusted).

Whether you're just curious or building if metal pulley is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if metal pulley is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Industrial Equipment Maintenance: This function can be used in manufacturing plants to automate inspections of metal pulleys, ensuring timely identification of rust. By recognizing rusted pulleys, maintenance teams can prioritize repairs and replacements, reducing unexpected downtime and extending equipment life.

- Quality Control in Manufacturing: In production lines that use metal pulleys, this classification can be integrated into quality control systems. Detecting rust early allows manufacturers to maintain product integrity and ensure that components meet safety and performance standards.

- Predictive Maintenance Solutions: Companies can implement this classification system in predictive maintenance software to forecast equipment failures associated with rusted pulleys. By analyzing trends in rust detection, businesses can schedule maintenance activities and minimize operational disruptions.

- Inspection Drones: This identifier can be used in drones equipped with cameras to inspect hard-to-reach industrial sites. By flying over machinery, drones can autonomously detect rusted metal pulleys, saving time and reducing the risk to human inspectors.

- Asset Management Systems: This function can enhance asset management platforms by integrating rust identification capabilities. When a rusted pulley is detected, the system can trigger alerts and update maintenance records automatically, ensuring a proactive approach to asset upkeep.

- Environmental Monitoring Compliance: Industries must comply with environmental regulations regarding equipment maintenance. This rust detection function can help companies stay in compliance by identifying equipment conditions that may lead to safety hazards or environmental violations.

- Training and Simulation Programs: The identifier can be incorporated into training systems for maintenance personnel. By simulating the detection of rusted pulleys in training environments, new employees can learn to recognize maintenance issues before they encounter them in real-world settings.