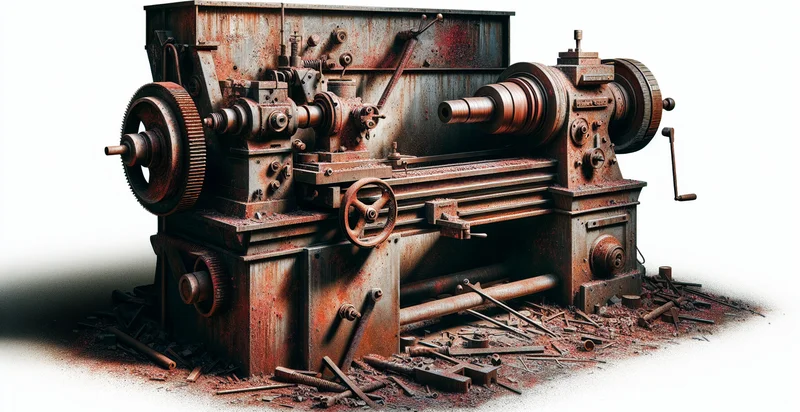

Identify if metal lathe is rusted

using AI

Below is a free classifier to identify if metal lathe is rusted. Just upload your image, and our AI will predict if the metal lathe is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-metal-lathe-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-metal-lathe-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-metal-lathe-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the metal lathe is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the metal lathe is rusted).

Whether you're just curious or building if metal lathe is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if metal lathe is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: By utilizing the rust identification function, manufacturers can implement predictive maintenance for metal lathes. This enables them to schedule timely maintenance, reducing downtime and preventing costly repairs due to unforeseen equipment failure.

- Quality Control: In a production environment, the rust detection capability can be integrated into a quality control system. This ensures that any metal lathe exhibiting signs of rust is flagged for inspection or replacement, thereby maintaining product quality and safety standards.

- Asset Management: Companies can enhance their asset management strategies by monitoring the condition of metal lathes. Identifying rusted machinery allows for more informed decisions regarding asset refurbishment or disposal, optimizing resource allocation.

- Safety Compliance: The rust detector can serve as a tool to help businesses comply with safety regulations. By ensuring that all machineries, including metal lathes, are rust-free, organizations can mitigate risks associated with operational hazards.

- Inventory Management: In inventory settings, the rust detection function can facilitate improved inventory accuracy. It allows for the classification of equipment's condition, ensuring that rusted tools are removed from circulation and reducing potential losses.

- Environmental Impact Assessment: Businesses can utilize rust detection to minimize environmental risks associated with rusted machinery, such as leaks and spills. This functional insight enables proactive measures to protect the environment and adhere to sustainability commitments.

- Training and Maintenance Protocols: This identification tool can inform training programs for workers on how to identify and manage equipment conditions. By incorporating rust detection into training, employees can be better prepared to maintain machinery, ensuring a culture of proactive equipment care and responsibility.