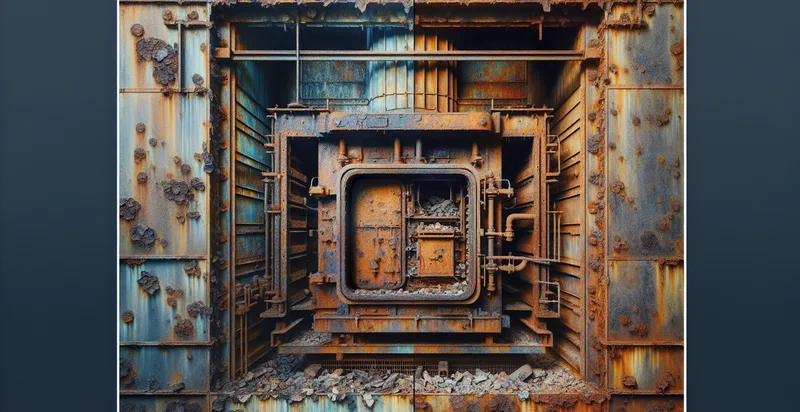

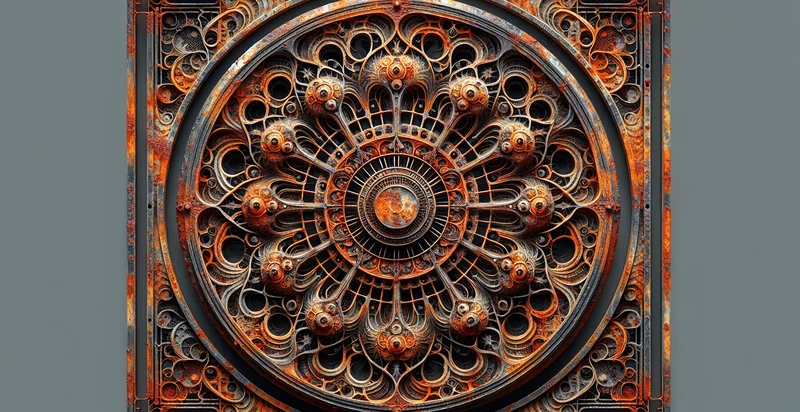

Identify if machine part is rusted

using AI

Below is a free classifier to identify if machine part is rusted. Just upload your image, and our AI will predict if the machine part is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-machine-part-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-machine-part-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-machine-part-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the machine part is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the machine part is rusted).

Whether you're just curious or building if machine part is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if machine part is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Manufacturing Quality Control: Implement the rust identification function in manufacturing settings to automate the inspection of machine parts. This enables quality control teams to quickly detect rust and prevent defective products from reaching customers.

- Predictive Maintenance: Use the rust identification feature to monitor the condition of machinery over time. By identifying rust early, businesses can schedule maintenance proactively, reducing downtime and extending the lifespan of equipment.

- Supply Chain Management: Integrate the rust identifier into the supply chain process to assess the condition of machine parts received from suppliers. This ensures that only quality components are used in production, minimizing the risk of failures due to rusted parts.

- Safety Compliance Audits: Leverage rust detection capabilities in safety audits of industrial equipment to ensure compliance with regulations. Identifying rust can prevent potential accidents and enhance workplace safety by addressing equipment deterioration promptly.

- Inventory Management: Apply the rust identification function to track and categorize machine parts in inventory. By flagging rusted items, companies can make informed decisions about reordering, refurbishing, or retiring parts, optimizing inventory costs.

- Asset Lifecycle Management: Use the rust detection function as part of an asset management strategy to monitor and evaluate the condition of machinery throughout its lifecycle. This data can inform investment decisions and improve overall asset performance.

- Training and Development: Incorporate rust identification training into employee development programs for factory workers and maintenance teams. Enhancing their skills in recognizing corrosion issues can improve their effectiveness in maintaining equipment and promote a culture of proactive maintenance.