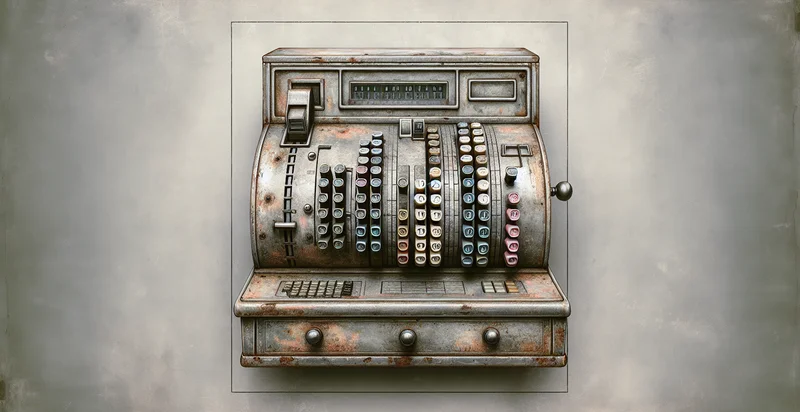

Identify if gear is rusted

using AI

Below is a free classifier to identify if gear is rusted. Just upload your image, and our AI will predict if the gear is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-gear-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-gear-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-gear-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the gear is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the gear is rusted).

Whether you're just curious or building if gear is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if gear is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Equipment Maintenance Alerts: This functionality can be integrated into maintenance management systems to automatically identify rusted gears on machinery. By receiving immediate alerts, maintenance teams can proactively address issues, reducing downtime and repair costs.

- Predictive Maintenance Insights: By analyzing the frequency and extent of rusting in gears, businesses can develop predictive maintenance schedules. This ensures that high-risk equipment is serviced before failure, thereby extending the life of the machinery and saving on operational costs.

- Quality Control in Manufacturing: In manufacturing environments, this image classification can be utilized to enhance quality assurance processes. Rust detection can be automated during product inspections, ensuring only high-quality components are shipped to clients.

- Inventory Management: Organizations can leverage this function to monitor the condition of spare gears in inventory. By identifying rusted components, businesses can streamline procurement processes and maintain optimal stock levels of quality parts.

- Safety Compliance Monitoring: The rust detection feature can help in compliance with safety regulations by identifying components that may pose safety risks. Regular monitoring of gear conditions can lead to a safer working environment and reduce liability for organizations.

- Asset Lifecycle Management: Businesses can utilize rust detection to assess the condition of gears as part of their asset management strategies. This promotes timely replacements and upgrades, contributing to efficient asset lifecycle management and cost control.

- Remote Surveillance in Harsh Environments: This technology can be deployed in remote or harsh environments where human inspection is challenging. Real-time rust detection through image classification can help ensure that equipment remains in good working condition, minimizing operational disruptions.