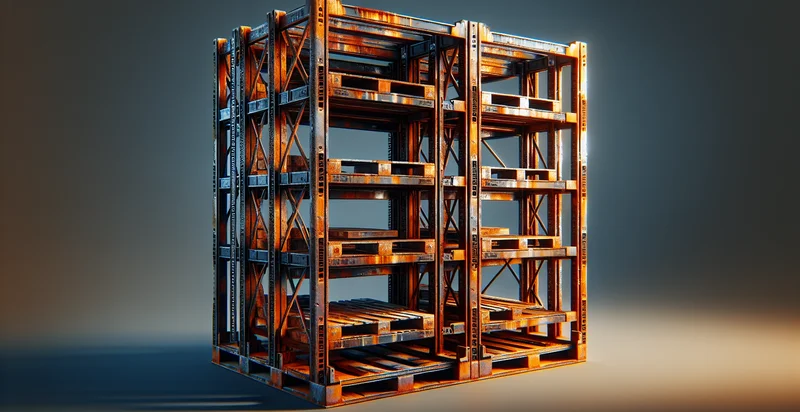

Identify if equipment rack is rusted

using AI

Below is a free classifier to identify if equipment rack is rusted. Just upload your image, and our AI will predict if the equipment rack is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-equipment-rack-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-equipment-rack-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-equipment-rack-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the equipment rack is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the equipment rack is rusted).

Whether you're just curious or building if equipment rack is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if equipment rack is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

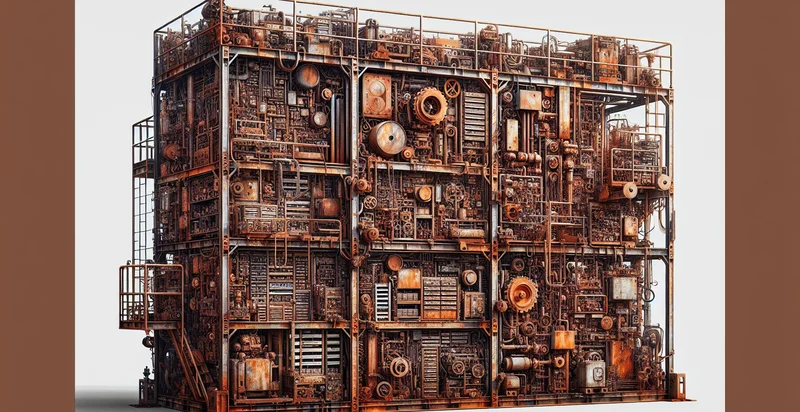

- Preventive Maintenance Scheduling: This use case involves the use of rust identification to schedule maintenance before equipment failures occur. By regularly monitoring equipment racks for signs of rust, companies can proactively address corrosion issues and extend the lifespan of their equipment.

- Inventory Management: This use case utilizes rust detection to classify the condition of stored equipment. By identifying rusted racks, inventory managers can prioritize repairs or replacements to optimize asset management and reduce operational risks.

- Safety Compliance Monitoring: Organizations can implement this identifier to ensure workplace safety standards are met. By regularly checking for rust on equipment racks, compliance officers can identify hazardous conditions that may lead to accidents or equipment failures, thereby enhancing workplace safety.

- Quality Assurance in Manufacturing: In manufacturing, identifying rust on equipment racks can be part of quality control processes. By ensuring that all equipment meets rust-free standards, manufacturers can maintain product quality and prevent contamination from corroded materials.

- Life Cycle Assessment: This use case integrates rust detection into environmental sustainability assessments. By identifying equipment deterioration caused by rust, businesses can make informed decisions about equipment replacement and recycling, thereby minimizing environmental impact.

- Insurance Claim Support: Companies can utilize rust identification to support insurance claims related to equipment malfunction or damage. Documenting rust issues can provide evidence needed for claims processing and help businesses recover costs associated with equipment failures.

- Asset Valuation Determination: In the context of asset valuation, identifying rust on equipment racks can significantly affect the appraised value. Companies can accurately assess the condition of their assets and adjust their valuations based on the findings, aiding in financial reporting and investment decisions.