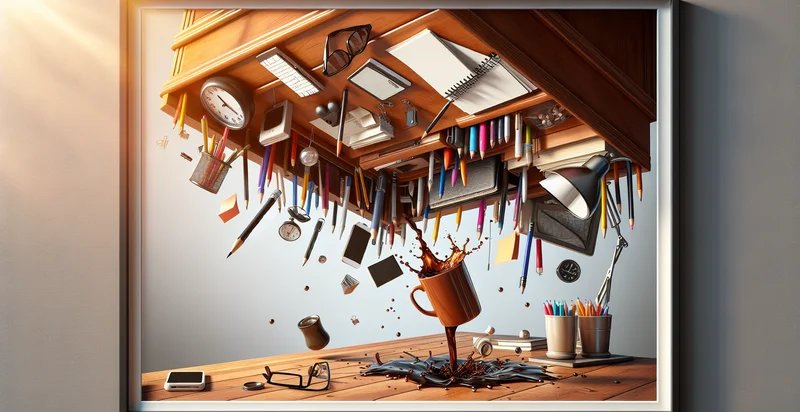

Identify if binder is upside down

using AI

Below is a free classifier to identify if binder is upside down. Just upload your image, and our AI will predict if the binder is upside down - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-binder-is-upside-down", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-binder-is-upside-down/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-binder-is-upside-down/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the binder is upside down.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Binder Right Side Up and Binder Upside Down.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the binder is upside down).

Whether you're just curious or building if binder is upside down detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if binder is upside down at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: Implement the binder orientation identification in manufacturing facilities to ensure that binders are assembled and packaged correctly. Detecting upside-down binders at the production line helps maintain product quality and reduce the number of returns due to misaligned products.

- Shipping and Logistics Management: Integrate the function in shipping warehouses to check that binders are oriented properly before dispatch. This prevents potential damage during transit and ensures a higher level of customer satisfaction upon receipt.

- Retail Inventory Management: Utilize the identification function in retail settings to monitor the orientation of binders on store shelves. This can help maintain an organized display, making it easier for customers to find products and reducing the risk of misplaced inventory.

- Automation in Office Supply Procurement: Use the identifier in automated supply procurement systems to verify binder orientation when receiving shipments. This automation ensures that only correctly oriented binders are accepted into inventory, streamlining the supply chain process.

- Machine Learning Model Training: Leverage the data from the binder orientation function to improve machine learning algorithms focused on visual recognition tasks. Aggregating data about binder misalignment can help train models that enhance general image classification capabilities across various retail environments.

- User Interface for Inventory Audits: Incorporate the functionality in mobile or web applications used for inventory audits. Field workers can quickly assess whether binders are correctly oriented, reducing the time spent on manual checks and improving audit accuracy.

- Customer Service Automation: Implement the identifier in customer service applications to evaluate binder product images uploaded by customers. This can help automate troubleshooting processes, guiding customers through returns or exchanges based on incorrectly oriented binders.