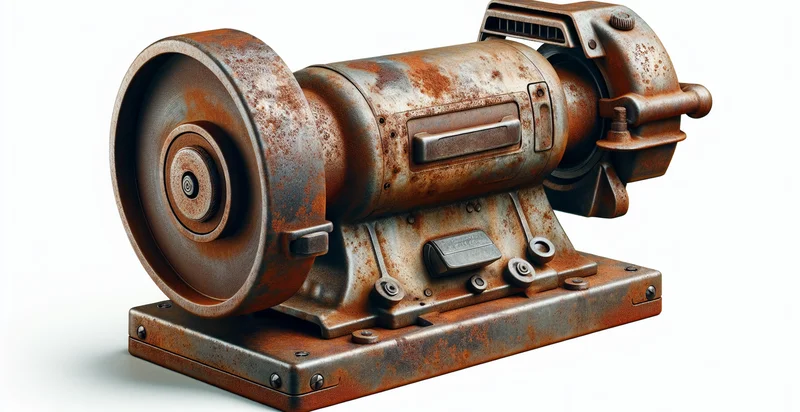

Identify if bench grinder is rusted

using AI

Below is a free classifier to identify if bench grinder is rusted. Just upload your image, and our AI will predict if the bench grinder is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-bench-grinder-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-bench-grinder-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-bench-grinder-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the bench grinder is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the bench grinder is rusted).

Whether you're just curious or building if bench grinder is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if bench grinder is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Maintenance Scheduling: This use case involves utilizing the rust identification function to automate maintenance scheduling for bench grinders. When rust is detected, the system can trigger alerts to maintenance teams, ensuring timely interventions that prevent further degradation of equipment.

- Safety Compliance: Companies can integrate this function to monitor the condition of bench grinders for compliance with safety regulations. Identifying rust promptly allows businesses to take corrective actions, reducing the risk of accidents caused by improperly maintained tools.

- Inventory Management: By analyzing the rust status of grinders, businesses can streamline their inventory management. This information can inform decisions regarding repairs versus replacements, optimizing resource allocation and minimizing downtime.

- Quality Control: Manufacturers can use rust identification as part of their quality control process. By ensuring that all bench grinders are free of rust, companies can maintain high standards for product reliability and performance, leading to improved customer satisfaction.

- Predictive Maintenance: Implementing this function allows for predictive maintenance strategies. Data from rust identification can be analyzed over time to forecast potential failures, enabling proactive replacements and maintenance that reduce operational costs.

- Training and Guidelines: This feature can support training programs for operators and maintenance personnel. By highlighting the importance of rust detection and its implications for equipment lifespan, it fosters a culture of care and responsibility around tool maintenance.

- Warranty Claims: Businesses can leverage rust detection data when processing warranty claims for bench grinders. By documenting rust issues, companies can validate claims related to equipment failure, ensuring that warranty terms are appropriately applied and upheld.