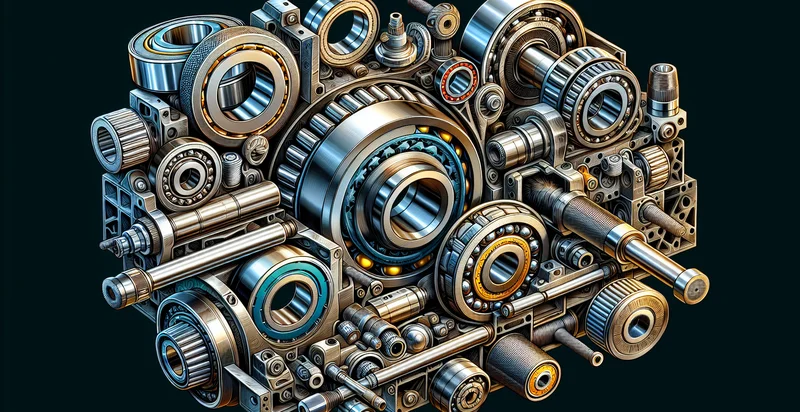

Identify if bearing is rusted

using AI

Below is a free classifier to identify if bearing is rusted. Just upload your image, and our AI will predict if the bearing is rusted - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-bearing-is-rusted", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-bearing-is-rusted/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-bearing-is-rusted/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the bearing is rusted.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Not Rusted and Rusted.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the bearing is rusted).

Whether you're just curious or building if bearing is rusted detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if bearing is rusted at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance: By integrating the rusted bearing identifier into machinery monitoring systems, organizations can predict potential failures before they occur. This proactive approach helps in planning maintenance activities and minimizing unexpected downtime.

- Quality Control in Manufacturing: Implementing this image classification function in production lines allows manufacturers to quickly identify rusted bearings during quality checks. This ensures that only components meeting quality standards are used, enhancing overall product reliability.

- Inventory Management: The identifier can assist in inventory systems by flagging rusted bearings that need replacement. This leads to improved stock management and reduces the risk of using compromised parts in critical machinery.

- Fleet Management: Transportation companies can use the rusted bearing identification feature to monitor the condition of fleet vehicles. Identifying rusted bearings early helps avoid breakdowns and extend the lifespan of vehicle components.

- Safety Inspections: Safety-critical industries can leverage this function to perform regular inspections of equipment. Identifying rusted bearings is crucial as they can pose safety hazards, thus ensuring compliance with safety regulations.

- Equipment Valuation: In asset management, the identifier can be used to assess the condition of machinery for valuation purposes. Knowing the state of bearings helps appraisers determine the resale value and investment needs of industrial equipment.

- Training and Simulation: Companies can use the identifier in training programs for maintenance technicians. By simulating scenarios where bearings are rusted, trainees can learn to identify and address such issues more effectively in real-world applications.