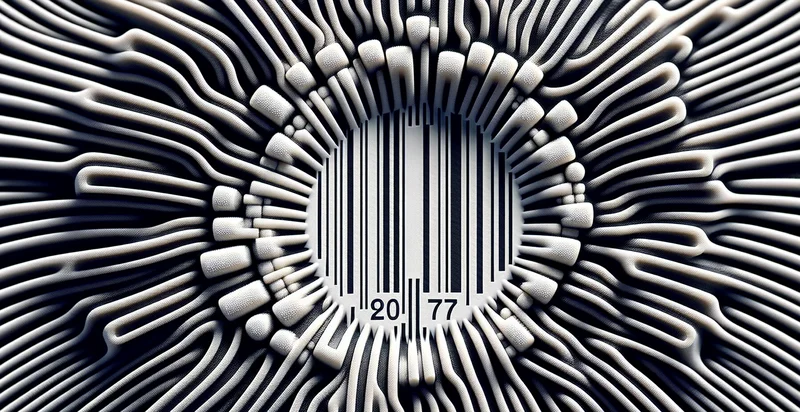

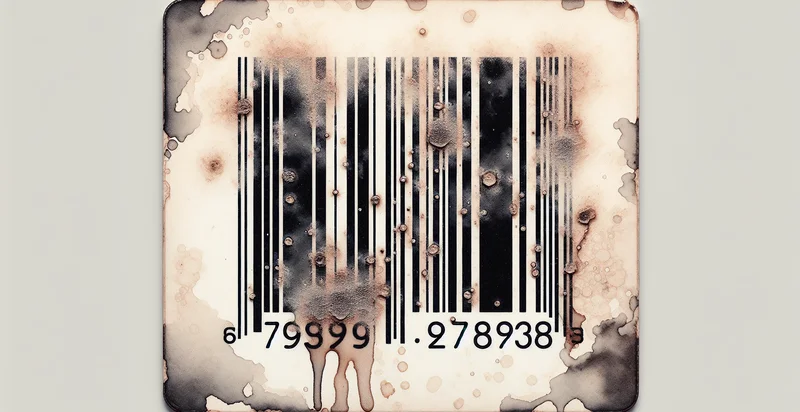

Identify if barcode surface is damaged

using AI

Below is a free classifier to identify if barcode surface is damaged. Just upload your image, and our AI will predict if the barcode is readable - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-barcode-surface-is-damaged", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-barcode-surface-is-damaged/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-barcode-surface-is-damaged/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if the barcode is readable.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Damaged and Intact.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if the barcode is readable).

Whether you're just curious or building if barcode surface is damaged detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if barcode surface is damaged at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Inventory Management: Retailers can utilize the barcode surface damage identifier to assess the condition of products during inventory scans. This functionality allows them to quickly identify items that may need to be removed or returned, ensuring that only sellable goods are on the shelves.

- Quality Control in Manufacturing: In manufacturing environments, this function can be applied in quality control processes to ensure barcodes are intact before the product moves to packaging or shipping. By preventing damaged barcodes from being sent out, companies can reduce errors and improve tracking throughout the supply chain.

- E-commerce Fulfillment: E-commerce companies can implement this identifier during the fulfillment process to verify the quality of products being shipped to customers. If a damaged barcode is detected, the item can be flagged for re-scanning or repackaging before it reaches the customer.

- Warehouse Logistics: Warehouses can use this function during the receiving process to assess the condition of incoming inventory. Identifying damaged barcodes early allows for timely resolution, reducing the risk of misplaced or untracked items.

- Returns Processing: Retailers can enhance their returns processing systems by integrating barcode surface damage detection. This ensures that returned items are verified for barcode integrity, helping to streamline the returns process and reduce the chance of error in restocking.

- Field Service Operations: Service technicians can leverage this function when checking-in equipment or parts in the field. By identifying any damaged barcodes on the spot, they can take corrective action, ensuring accurate inventory tracking and reporting.

- Regulatory Compliance: Industries with strict compliance requirements, such as pharmaceuticals, can implement this identifier to confirm the integrity of product barcodes. By ensuring that damaged barcodes are addressed, companies can prevent regulatory breaches and maintain traceability of their products.