Identify if barcode shows wear

using AI

Below is a free classifier to identify if barcode shows wear. Just upload your image, and our AI will predict if it’s damaged - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-barcode-shows-wear", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-barcode-shows-wear/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-barcode-shows-wear/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if it’s damaged.

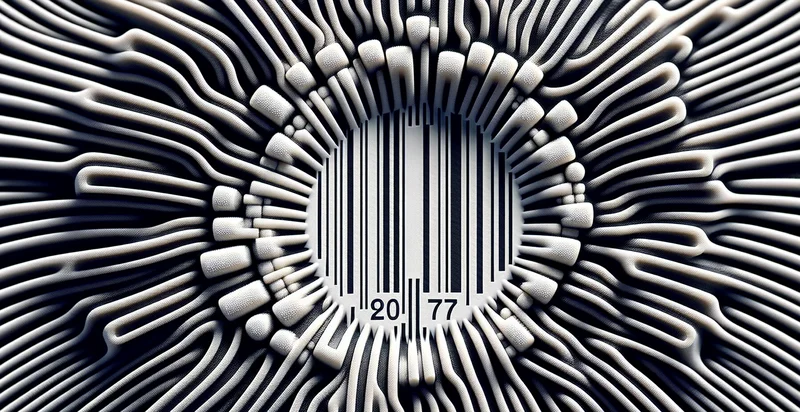

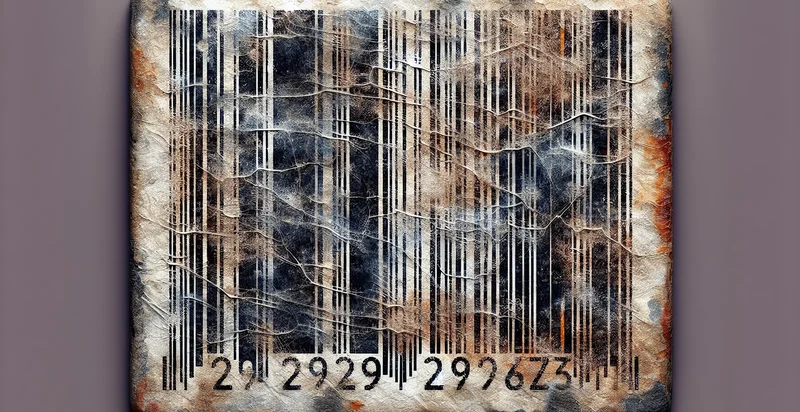

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Pristine and Worn.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if it’s damaged).

Whether you're just curious or building if barcode shows wear detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if barcode shows wear at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: This use case involves the integration of the barcode wear identifier in manufacturing production lines. By identifying worn barcodes on products, companies can prevent mislabeling and ensure accurate tracking of inventory, reducing errors and improving operational efficiency.

- Retail Inventory Management: Retailers can utilize the barcode wear identifier to monitor product labels throughout various storage and display environments. By identifying and flagging worn barcodes, store managers can initiate label replacements, ensuring that customers have access to accurate product information and pricing.

- Logistics and Supply Chain Optimization: In logistics, worn barcodes on shipping containers can lead to delays and misrouted packages. The barcode wear identifier enables logistics companies to conduct inspections of barcodes in transit, allowing for timely interventions that prevent shipping errors and improve overall supply chain efficiency.

- Automated Checkout Systems: By integrating the worn barcode identifier in self-checkout kiosks, retailers can enhance customer experience. The system can prompt staff to replace unreadable barcodes, minimizing checkout delays and enhancing customer satisfaction through quick resolution of issues.

- Product Recall Management: In the event of a product recall, the barcode wear identifier can assist companies in quickly locating and removing affected products from shelves. By ensuring that all barcodes are legible and intact, businesses can facilitate efficient coordination for recalls and protect consumer safety.

- Healthcare Inventory Tracking: In healthcare settings, managing pharmaceuticals and medical supplies is critical. The barcode wear identifier can help hospitals ensure that all products are appropriately tracked, preventing mix-ups and ensuring that staff can easily access accurate information about their supplies.

- E-commerce Fulfillment Accuracy: E-commerce companies can implement the barcode wear identifier to monitor product labels during the picking and packing processes. By ensuring that no worn barcodes are shipped to customers, companies can reduce return rates due to labeling errors and enhance customer trust and satisfaction.