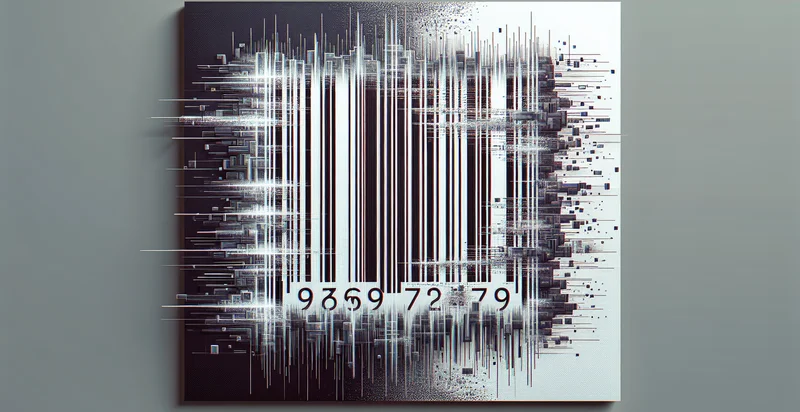

Identify if barcode shows heat damage

using AI

Below is a free classifier to identify if barcode shows heat damage. Just upload your image, and our AI will predict if there is heat damage - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("if-barcode-shows-heat-damage", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/if-barcode-shows-heat-damage/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/if-barcode-shows-heat-damage/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict if there is heat damage.

This pretrained image model uses a Nyckel-created dataset and has 2 labels, including Heat Damaged and Intact.

We'll also show a confidence score (the higher the number, the more confident the AI model is around if there is heat damage).

Whether you're just curious or building if barcode shows heat damage detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify if barcode shows heat damage at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Warehouse Quality Control: Implement the barcode heat damage identifier in warehouse environments to automate quality assessment of stored products. This allows personnel to quickly identify heat-damaged items without manual inspections, minimizing wastage and ensuring product integrity.

- Retail Inventory Management: Integrate the identifier into retail inventory systems to assess product conditions upon arrival or during stock audits. This ensures that damaged goods are removed from shelves promptly, improving customer satisfaction and reducing returns.

- Supply Chain Monitoring: Use the barcode analysis in supply chain logistics to evaluate products during transportation. By identifying heat damage in real-time, companies can take corrective actions swiftly, preventing damaged goods from reaching retailers or end consumers.

- Food Safety Protocols: Deploy the identifier in food distribution channels to monitor perishable goods susceptible to heat damage. This functionality can alert staff about compromised items, thereby ensuring compliance with food safety regulations and protecting consumers' health.

- E-commerce Returns Management: Incorporate the identifier in e-commerce logistics to assess returned products for heat damage automatically. By identifying and cataloging damaged items, companies can streamline return processes and improve reselling strategies.

- Pharmaceutical Product Integrity: Implement the barcode heat damage identifier in the pharmaceutical industry to monitor temperature-sensitive medications. This procedure safeguards against the sale of compromised drugs, protecting patient safety and maintaining regulatory compliance.

- Cold Chain Monitoring Solutions: Integrate the identifier into cold chain monitoring technologies for industries that rely on temperature-sensitive products. By continuously checking for heat damage via barcodes, businesses can enhance product tracking and ensure optimal storage conditions throughout the supply chain.