Identify hydraulic system conditions

using AI

Below is a free classifier to identify hydraulic system conditions. Just upload your image, and our AI will predict the condition of the hydraulic system. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("hydraulic-system-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/hydraulic-system-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/hydraulic-system-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the hydraulic system..

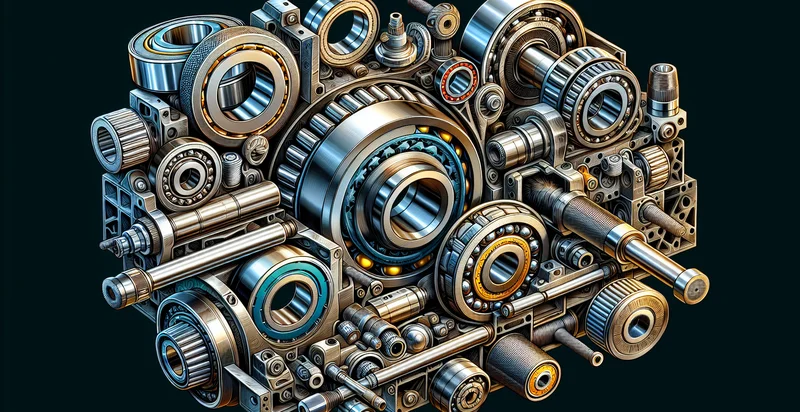

This pretrained image model uses a Nyckel-created dataset and has 12 labels, including Acceptable Condition, Critical Condition, Degraded Condition, Excellent Condition, Fair Condition, Good Condition, Non Operational Condition, Normal Condition, Operational Condition and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the hydraulic system.).

Whether you're just curious or building hydraulic system conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify hydraulic system conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

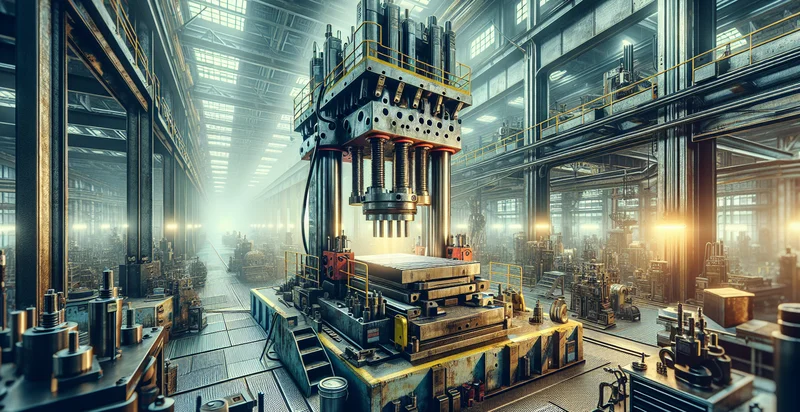

- Predictive Maintenance: The false image classification function can be employed to analyze hydraulic system conditions for predicting maintenance needs. By identifying anomalies in hydraulic system images, it enables proactive maintenance actions, reducing downtime and operational costs.

- Quality Assurance: In manufacturing settings, this function can be used to ensure that hydraulic components meet quality standards. By classifying images of hydraulic systems, businesses can detect faulty parts early in the production process, minimizing waste and improving product reliability.

- Compliance Tracking: Organizations can utilize the false image classification function to ensure compliance with safety regulations for hydraulic systems. By continuously monitoring the condition of the systems through image analysis, companies can maintain adherence to industry standards and regulations, reducing the risk of fines or shutdowns.

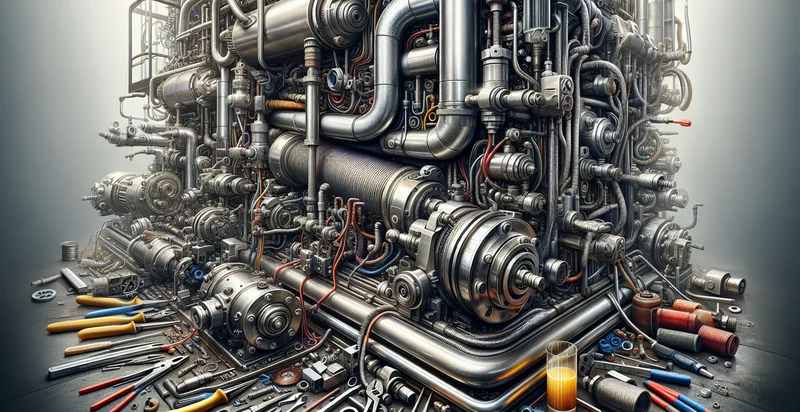

- Training and Simulation: This technology can enhance training programs for technicians working with hydraulic systems. By providing real-time feedback on system conditions through image classification, trainees can better understand system faults and learn effective troubleshooting techniques.

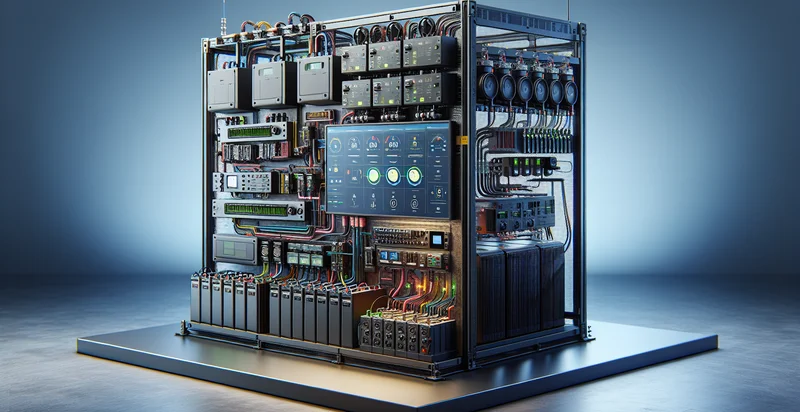

- Remote Monitoring: The classification function can be integrated into remote monitoring systems for hydraulic setups. It allows operators to receive alerts about system issues based on image analysis, enabling them to address problems promptly without the need for physical inspections.

- Performance Optimization: Businesses can use the function to analyze and optimize the performance of hydraulic systems. By identifying inefficiencies through image classifications, companies can make informed decisions on system adjustments, leading to improved energy efficiency and overall productivity.

- Incident Investigation: In the event of system failures, this classification function can aid in incident investigations. By classifying and analyzing images of hydraulic systems post-incident, organizations can determine the root causes, allowing them to implement corrective measures and prevent future occurrences.