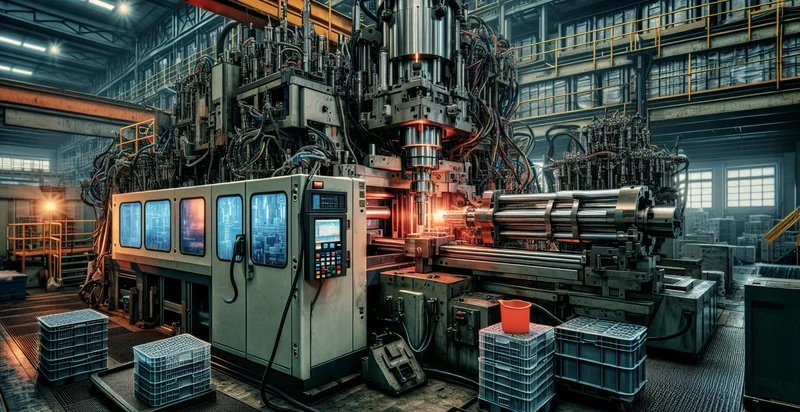

Identify grinding machine conditions

using AI

Below is a free classifier to identify grinding machine conditions. Just upload your image, and our AI will predict the condition of the grinding machine - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("grinding-machine-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/grinding-machine-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/grinding-machine-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the grinding machine.

This pretrained image model uses a Nyckel-created dataset and has 4 labels, including Excellent Condition, Fair Condition, Good Condition and Poor Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the grinding machine).

Whether you're just curious or building grinding machine conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify grinding machine conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance Alerts: This function can analyze the operational conditions of grinding machines in real-time to identify any anomalies that may indicate potential failures. By providing timely alerts, maintenance teams can perform preventative maintenance, reducing downtime and repair costs.

- Quality Control Automation: By classifying images of the ground materials, businesses can monitor the quality of the finished product automatically. This ensures that any deviations from quality standards are promptly flagged, allowing for immediate corrective actions to be taken.

- Operator Training Tool: The image classification function can be used in training modules for new operators of grinding machines. By providing insights into normal versus abnormal machine conditions, it can enhance the learning experience and improve operator competency.

- Production Efficiency Optimization: Analyzing the conditions of grinding machines helps in understanding the relationship between machine performance and output quality. This data can be utilized to optimize production processes, reducing waste, and improving efficiency across the operation.

- Root Cause Analysis in Failure Investigations: When a grinding machine fails or exhibits poor performance, the function can assist in the analysis of historical images related to the failure. This information helps in identifying root causes, leading to more effective strategic improvements and design changes.

- Compliance and Regulatory Reporting: In industries with strict regulatory standards, this function can assist in generating compliance reports based on the visual assessment of grinding machine conditions. This documentation is essential for audits and maintaining operational transparency.

- Remote Monitoring Solutions: For companies with multiple sites, this image classification function can facilitate remote monitoring of grinding machines. By continuously analyzing images, it enables centralized oversight and quick decision-making from a distance, improving overall operational management.