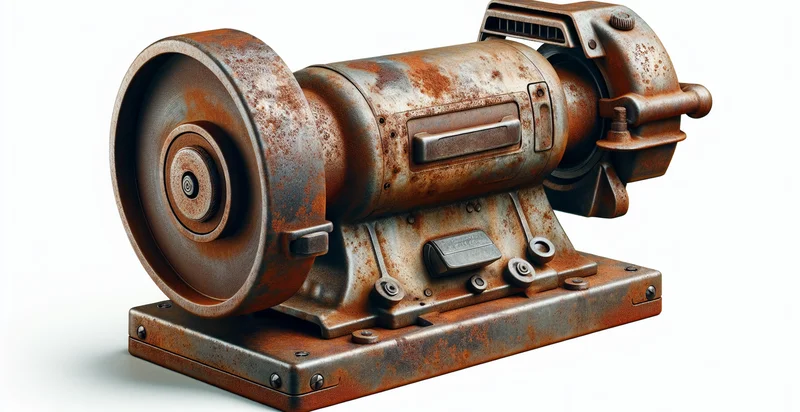

Identify grinder type

using AI

Below is a free classifier to identify grinder type. Just upload your image, and our AI will predict what type of grinder it is - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("grinder-type", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/grinder-type/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/grinder-type/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict what type of grinder it is.

This pretrained image model uses a Nyckel-created dataset and has 20 labels, including Angle Grinder, Belt Grinder, Bench Grinder, Blade Grinder, Carbide Grinder, Coffee Grinder, Die Grinder, Electric Grinder, Floor Grinder and Handheld Grinder.

We'll also show a confidence score (the higher the number, the more confident the AI model is around what type of grinder it is).

Whether you're just curious or building grinder type detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify grinder type at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Quality Control in Manufacturing: This use case involves integrating the 'grinder type' identifier into quality assurance processes within manufacturing facilities. By automatically classifying the type of grinder used, companies can ensure that the proper grinder type is deployed, reducing the risk of product defects caused by incorrect machinery.

- Equipment Maintenance Scheduling: The 'grinder type' identifier can be utilized to optimize maintenance schedules for different types of grinders. By identifying the specific type of grinder, maintenance teams can implement targeted checks and repairs, minimizing downtime and extending the lifespan of the equipment.

- Inventory Management: Businesses can use the grinder classification function to streamline inventory management for various grinder types. By accurately identifying grinder types in stock, companies can improve procurement processes, manage supply chains more effectively, and reduce inventory costs through optimized orders.

- Training and Safety Protocol Development: The identifier can serve as a basis for developing specific training programs for operators based on the type of grinder being used. This ensures that all personnel are well-trained in the handling and safety measures pertinent to each grinder type, leading to a safer work environment and improved operational efficiency.

- Product Traceability: Companies can leverage the function for traceability purposes by associating specific products with the grinder types used during their production. This allows for better tracking of production processes and can be crucial for quality audits and compliance with regulatory standards.

- Market Analysis and Trends: The 'grinder type' identifier can help businesses analyze market trends by categorizing sales data based on the different types of grinders. This insight can inform strategic decisions and investments, enabling companies to adapt to changing market demands and stay competitive.

- Customer Support and Troubleshooting: The identifier can assist customer service teams in troubleshooting machine-related issues by quickly determining the type of grinder a customer operates. This targeted support can enhance response times and improve customer satisfaction by providing tailored assistance based on the specific grinder type involved.