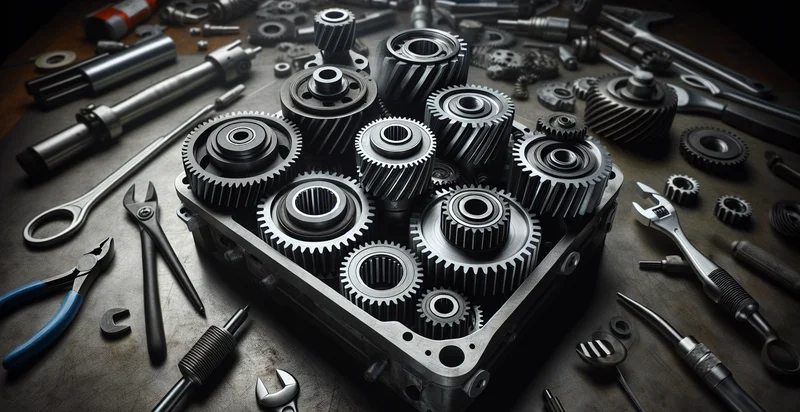

Identify gear box conditions

using AI

Below is a free classifier to identify gear box conditions. Just upload your image, and our AI will predict the condition of the gear box. - in just seconds.

Contact us for API access

Or, use Nyckel to build highly-accurate custom classifiers in just minutes. No PhD required.

Get started

import nyckel

credentials = nyckel.Credentials("YOUR_CLIENT_ID", "YOUR_CLIENT_SECRET")

nyckel.invoke("gear-box-conditions", "your_image_url", credentials)

fetch('https://www.nyckel.com/v1/functions/gear-box-conditions/invoke', {

method: 'POST',

headers: {

'Authorization': 'Bearer ' + 'YOUR_BEARER_TOKEN',

'Content-Type': 'application/json',

},

body: JSON.stringify(

{"data": "your_image_url"}

)

})

.then(response => response.json())

.then(data => console.log(data));

curl -X POST \

-H "Content-Type: application/json" \

-H "Authorization: Bearer YOUR_BEARER_TOKEN" \

-d '{"data": "your_image_url"}' \

https://www.nyckel.com/v1/functions/gear-box-conditions/invoke

How this classifier works

To start, upload your image. Our AI tool will then predict the condition of the gear box..

This pretrained image model uses a Nyckel-created dataset and has 8 labels, including Damaged Condition, Excellent Condition, Fair Condition, Functional Condition, Good Condition, New Condition, Poor Condition and Worn Condition.

We'll also show a confidence score (the higher the number, the more confident the AI model is around the condition of the gear box.).

Whether you're just curious or building gear box conditions detection into your application, we hope our classifier proves helpful.

Related Classifiers

Need to identify gear box conditions at scale?

Get API or Zapier access to this classifier for free. It's perfect for:

- Predictive Maintenance Alerts: By using the gearbox conditions identifier, organizations can predict potential failures before they happen. This proactive approach helps in scheduling timely maintenance, reducing downtime, and extending the lifespan of gearboxes.

- Quality Control in Manufacturing: The function can be integrated into the manufacturing process to monitor the quality of gearboxes in real-time. By identifying faulty gearboxes before they leave the factory, companies can minimize returns and enhance customer satisfaction.

- Performance Benchmarking: Companies can use the gearbox condition data to benchmark performance against industry standards. This can help in evaluating the effectiveness of operations and the durability of materials used in gearbox production.

- Fleet Management Optimization: This function can be employed in industries with heavy machinery fleets to monitor gearbox conditions continually. By analyzing the data, fleet managers can optimize operational efficiency, ensuring vehicles are serviced only when necessary.

- Safety Compliance Monitoring: The gearbox condition identifier can be crucial for monitoring compliance with safety regulations in industries like mining or construction. Regular assessments of gearbox conditions can help mitigate safety risks associated with equipment failures.

- Customized Maintenance Plans: Organizations can utilize the insights gained from the gearbox conditions identifier to develop tailored maintenance plans. By focusing on the specific needs of each gearbox based on its condition, businesses can allocate resources more effectively and reduce costs.

- IIoT Integration: This function can be integrated with Industrial Internet of Things (IIoT) platforms to facilitate real-time monitoring of gearbox conditions. By connecting to various sensors, organizations can leverage advanced analytics and machine learning to enhance decision-making processes across their operations.